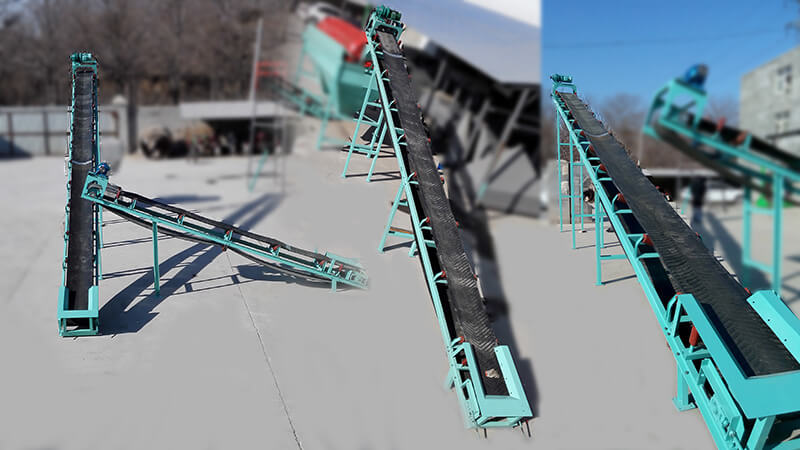

Belt Conveyor System is an indispensable part in the whole fertilizer production line. We provide customers with inclined belt conveyor and high

| Advantage of Fertilizer Belt Conveyor System ● Compact design, suitable for grain, powder or fertilizer products. ● Grooves used to fasten attachment parts, such as stands, side rails or proximity switches ● Profile design ensures a torsion-resistant structure with good carrying characteristics ● Crowned pivot rollers and idler rollers allow center belt run and facilitate belt adjustment ● Optional rubberized drive rollers ensure optimal transmission of torque |

Application of Organic & Compound Fertilizer Conveyer Belt The material handling conveyors are widely used in mining, metallurgy, chemical industry, foundry, building materials industry,and fertilizer production lines. According to transportation requirements, customers can choose both single conveyor or multiple conveyors.It is suitable for the transportation of powder, granular, such as coal, gravel, sand, cement, fertilizer, food, etc. Its length and assembly type can be provided in accordance with users’ requirements. |

1. Locate belt by moving the motor

2. Put belts onto the pulley one by one and locate belts first on the driving pulley

3. Do not use a lever to force belt onto pulleys but turning pulley slowly can facilitate installation.

4. Apply tension to prevent slippage at full loading and run 5 minutes and re-tension. If necessary, please re-adjust the tension after belts running a few days.

5. Do not combine to use new and used belts in one set that may shorten belt life due to unbalanced stretch of belts.

Proper Care As Below:

1. Check pulleys and make them aligned. Incorrect alignment may shorten the service belt life.

2. Check the pulley main components and lubricate the working parts periodically.

3. Pay attention to the pulley grooves and make sure they are all equal in dimensions.

4. Check the pulley abrasion and remove any rust, dirt or grease that may influence belt usage.

5. Ensure heat dissemination of pulley in belt operation.

Technical Data of Inclined Belt Conveyor

|

Model

|

Production Capacity (t/h)

|

Power(kw)

|

|

FY-B-500

|

6-10

|

3-4

|

|

FY-B-600

|

8-17

|

4-5.5

|