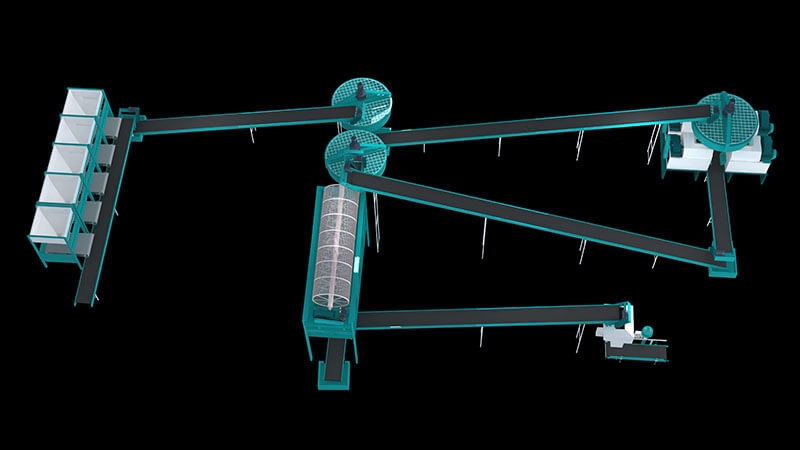

This production line is used for producing compound fertilizer with the annual output of 100,000 tons. The line adopts rotary drum granulator which has large capacity for fertilizer granulation, and can be used for producing high, medium and low concentrated compound fertilizer. Other machines in this fertilizer production line include batching machine, pan mixer, belt conveyor, rotary dryer, rotary cooler, rotary screen, rotary drum coating machine, finished products warehouse, automatic packing machine and chain crusher. We provide complete sets of equipment for compound fertilizer production and solutions for our esteemed customers!

Application of Rotary Drum Granulator Production Line

1. Rotary drum granulator line has wide adaptability to raw materials which can be urea, ammonium nitrate, ammonium chloride, ammonium sulfate, monoammonium phosphate(MAP), diammonium phosphate(DAP), single superphosphate(SSP), potassium chloride, potassium sulfate, etc. You can choose according to market demand and soil test results.

2. Rotary drum granulator fertilizer production line can produce compound fertilizer, organic fertilizer and organic compound fertilizer with the content of N, P, K ranging from 20-48%.

Advantages of Rotary Drum Granulator Production Line

1. Adopts advanced rotary drum granulator, the granulation rate can reach 70%.

2. Key parts adopt wear-resistant and corrosion-resistant materials, the equipment have long service life.

3. Adopt plastic plate or stainless steel plate lining, materials not easy to stick on the inner wall of the machine.

4. Stable operation, easy maintenance, high efficiency, low energy consumption.

5. Adopt belt conveyor to connect the whole line, reliazing continuous production.

6. Adopt two sets of dust settling chamber to deal with the tail gas, environment friendly.

7. Two times of screening process ensure qualified granules with uniform size.

8. Evenly mixing, drying, cooling, and coating, the finished product has superior quality.

Rotary Drum Compound Fertilizer Production Line Working Flow

1. Material Proportioning

The first process of the production line is proportioning process, where various raw materials are proportioned according to the formula. We adopt six bin batching machine here, which can complete proportioning automatically with high accuracy and high efficiency, ensuring the quality of finished products. After batching process, the materials are sent to the mixer by the belt conveyor.

2. Material Mixing

We use two pan mixers in this line for the mixing of raw materials. The mixers can fully mix the materials so that to increase the utilization rate of granular fertilizer. The inner side of the disc is made of polypropylene plate or stainless steel, which makes raw materials not easily sticky, and abrasion resistance. After mixing, the materials will be discharged through the outlet at the bottom, and sent to the fertilizer granulator by the belt conveyor.

3. Fertilizer Granulation

The evenly mixed materials enter into the rotary drum granulator from the feed end. With the constant rotating of the cylinder, the materials form a rolling bed. Under the extrusion force produced, the materials agglomerate into small particles, which become the core, attaching the powder around to form the qualified spherical granules, which finally discharge through the discharge end. Our rotary granulator has high fertilizer granulation rate, which can reach 70%. Lining with pvc plastic plate or stainless steel plate, the material is not easy to stick to the cylinder.

4. Fertilizer Drying

By the belt conveyor, the wet fertilizer enters into the rotary dryer from the feed hopper at the higher end. With the rotation of the cylinder, the wet fertilizer co-current contacts with the hot air suctioned from the hot blast stove and exchange heat, thus the moisture is evaporated. The dried granules discharge through the outlet at the lower end. The tail gas enters into the dust settling chamber.

5. Fertilizer Cooling

By the belt conveyor, the hot fertilizer from the dryer is sent into the rotary cooler through the feed hopper at the higher end. With the rotation of the cylinder, the materials counter-current contact with the suction cool air and exchange heat, thus the temperature is reduced. The cooled materials flow out from the lower end. The tail gas enters into the dust settling chamber.

6. First Screening

Cooled fertilizer granules enter into the rotary screener through the feed hopper at the higher end. With the rotation of the cylinder, unshaped granules passing through the screen aperture are discharged through the outlet at the bottom and sent back to the mixer, while shaped granules flow forward and discharge through the outlet at the lower end of the machine. The rotary screen adopts combined screen, which is easy for maintenance and replacement.

7. Second Screening

By the belt conveyor, shaped granules from previous process are sent to the second rotary screen, where qualified granules are discharged through the outlet at the bottom and sent to the coating machine, while unqualified particles are crushed and sent back to the mixer for re-granulation. The vertical

8. Fertilizer Coating

The conveyor belt sends the qualified granules from the second screen into the rotary coating machine from the higher end. With the rotation of the cylinder, powder or liquid are evenly coated on the surface of granules, which prevent caking, meanwhile increase the brightness and roundness of the granular. The machine is lined with polypropylene plate or stainless steel plate. After coating, the fertilizer granules discharge from the lower end of the cylinder.

9. Fertilizer Packaging

By the belt conveyor, the coated fertilizer are sent to the finished products warehouse to be packed by the automatic packing machine. We have designed two finished products warehouses and packing machines for this fertilizer production line. The packing machine can complete feeding, weighing, conveying and sealing process automatically. Packed fertilizer can be stored for sale.

Technical Data of 100,000 tons/year Rotary Drum Granulator Production Line

|

Item

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Quantity (set)

|

|

Six Bin Batching Machine

|

1

|

||||

|

Pan Mixer

|

FY-WSJB-90

|

2330X1070X1200

|

3-5

|

15

|

2

|

|

Rotary Drum Granulator

|

FY-ZGZL-22X80

|

8000x4300x3700

|

15-20

|

45

|

2

|

|

Rotary Drum Dryer

|

FY-HGJ-2.4

|

26000x2900x2900

|

20

|

45

|

1

|

|

Rotary Drum Cooler

|

FY-LQJ-2.2

|

23500x2600x2600

|

20

|

30

|

1

|

|

Rotary Drum Screening Machine

|

FY-GTSF-2.0X8

|

9800x2700x4700

|

20

|

15

|

2

|

|

Rotary Drum Coating Machine

|

FY-HBM-1.8X7

|

5-8

|

15

|

||

|

Chain Crusher

|

FY-LSFS-80

|

1250x1000x2100

|

2-8

|

22

|

1

|

|

Finished Products Warehouse

|

FY-CPC-2.0

|

2150x2150x4100

|

8-15

|

2

|

|

|

Automatic Packager

|

FY-DGS-50F

|

3-8bags/minute

|

1.5

|

2

|

|

|

Belt Conveyor

|

12

|

||||

|

Dust Settling Chamber

|

Drawing is provided

|

2

|

|||

|

Hot Blast Stove

|

Drawing is provided

|

1

|

NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.