Organic fertilizer produced by flat die granulator production line will provide crops with comprehensive nutrition, as this production line has a wide raw materials application. This 30,000 T/Y organic fertilizer granulation line can further process biologic materials, wastes of animal or plant nature, or crop residues to eliminate poisonous and deleterious substance with available nutrient elements, such as organic acids, peptides, nitrogen, phosphorus and potassium left.

Taking a chicken farm with 100,000 chickens as example, there are 6 tons solid waste and 60 tons waste water being produced every day. If the chicken manure are improperly disposed, undigested organic matters will decompose foul-smelling gas, such as ammonia, vinyl alcohol, hydrogen sulfide,

Fertilizer Granulation Process of Organic Fertilizer Production Line

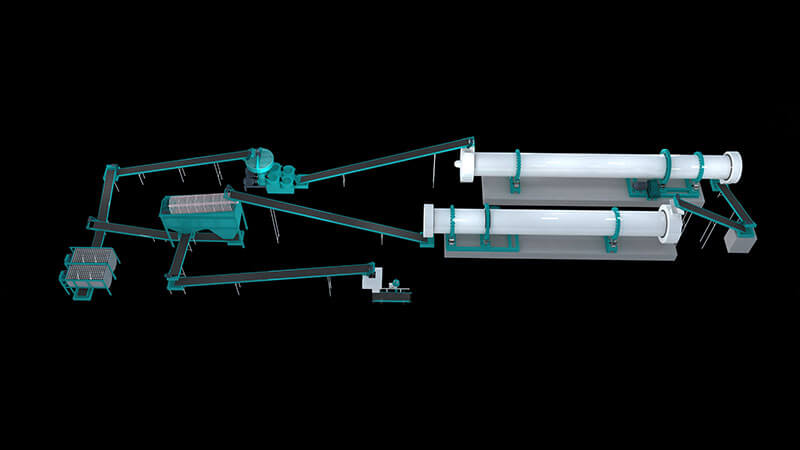

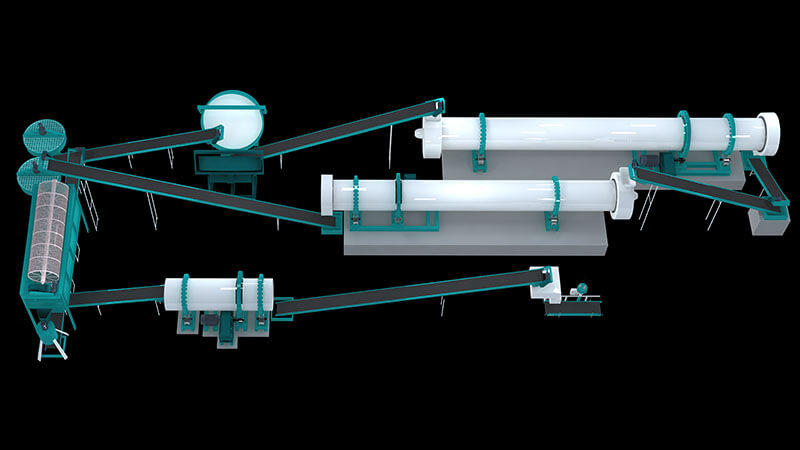

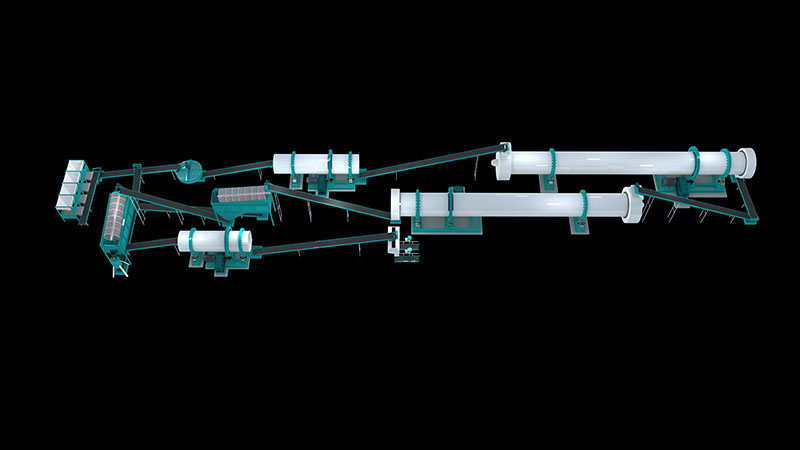

The 30,000 tons per year organic fertilizer production line consists of whole-set fertilizer granulation equipment with high technology. Double helix compost windrow turner, Horizontal mixer, Pan feeder, Flat die granulator, Organic fertilizer polishing machine, Rotary drum dryer/cooler/ screener, Automatic fertilizer packager, and Belt conveyor.

1.Manure Fermentation

Double helix compost turner is used for fermenting and composting organic waste, such as animals & fowls manure, sludge waste, sugar filter mud, oilseed residues and straw sawdust etc. There are two spiral arms moving in the trough. Materials can be mixed and fermented in the trough for 7-10 days. Temperature should be in 60-70℃ and moisture content should be between 40-50%.

2.Raw Materials Mixing

Fermented materials are mixed evenly together in horizontal mixer to improve fertilizer nutrient distribution uniformity and the greatest fertilizer nutrient use efficiency, which is also helpful for further granulating. The horizontal mixer machine is also suitable for feed, concentrated feed and additive premix mixing.

3. Materials Granulating

Evenly-mixed raw materials are transported into flat die granulator for pelletizing. The particles shape of organic fertilizer granulated by flat die fertilizer pellet mill is cylindrical. Usually, a fertilizer polishing machine, which is designed based on flat die extrusion granulator, is used to polish the granules into ball shape with easy operation.

4. Organic Fertilizer Drying & Cooling

The aim of drying process is to dry granules moisture, to increase fertilizer strength, convenient to store. After drying, due to too much heat, caking of fertilizer granules is easy to occur, so they need to be cooled in rotary drum cooler, easier to storage and

5.Organic Fertilizer Grading & Coating & Packaging

Unqualified fertilizers are screened out to re-granulate, while qualified ones are coated to increase the brightness and roundness of finished products, and then packaged for further storage.

Advantage of Flat Die Granulator Production Line

1.Turning Waste into Treasure

Raw materials of this organic fertilizer production line are fresh chicken manure and pig effluent, without any chemical composition. Chicken and pig have weak digestive functions, as a result, there is only 25% nutrients being consumed, with the other 75% being eliminated in the feces. If taking full advantage of those waste, bio fertilizer manufacturing process plant will definitely achieve better economic benefits, and also make great contributions to environment protection.

2. Large Profits with Small Investment

The bio organic fertilizer machines are with advanced technology, and reasonable structure, greatly increasing value of output per unit of labour and production value profit margin. Organic fertilizer production line is with high output value & high benefits. It not only saves energy and reduces consumption, but is with easy operation, stable function, and easier maintenance.

3. Changing the Status Quo of Imbalanced Fertilization

Unrational application of fertilizer does great harm to soil texture. While organic fertilizers produced by flat die granulator production line enrich in organic matter and nutrients, which will be a comprehensive nutrition supplement to the soil. Organic matter accelerate the activity of trace elements in soil, solving soil problems encountering in agricultural production.

Technical Data of Bio Fertilizer Production Line

|

Item

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Quantity (set)

|

|

Horizontal Mixer

|

FY-WSJB-90

|

2330X1070X1200

|

3-5

|

15

|

2

|

|

Pan Feeder

|

FY-YPWL-2000

|

2100x2100x1300

|

2.5-5

|

5.5

|

1

|

|

Flat Die Granulator

|

FY-KP-40

|

1200x650x1450

|

0.75-2

|

15

|

2

|

|

Fertilizer Polishing Machine

|

FY-1000×2

|

2200x1050x1300

|

0.8-1.6

|

8

|

2

|

|

Rotary Drum Dryer

|

FY-HGJ-1.2

|

13000x2360x1800

|

2-3

|

7.5

|

1

|

|

Rotary Drum Cooler

|

FY-LQJ-1.0

|

13000x2360x1800

|

2-3

|

7.5

|

1

|

|

Rotary Drum Screening Machine

|

FY-GTSF-1.2×4

|

5000x1600x3000

|

2-5

|

5.5

|

1

|

|

Finished Products Warehouse

|

FY-CPC-2.0

|

2150x2150x4100

|

8-15

|

2

|

|

|

Automatic Packager

|

FY-DGS-50F

|

3-8bags/minute

|

1.5

|

2

|

|

|

Belt Conveyor

|

9

|

||||

|

Dust Settling Chamber

|

Drawing is provided

|

1

|

|||

|

Hot Blast Stove

|

Drawing is provided

|

1

|

NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.