Fertilizer Rotary Drum Screen Machine Introduction

In fertilizer production, the fertilizer granular shall be screened before packaging to ensure the uniformity of the finished product. Rotary screener is a

Structure and Working Principle of Fertilizer Sifter Machine

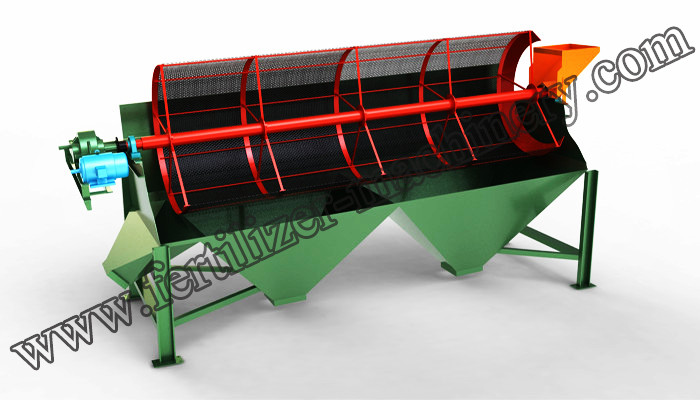

Rotary Fertilizer screening machine is composed of frame, rotary screen and driving part.

1. The frame of the rotary drum screen machine is welded by high quality steel plate and channel steel, and strictly meets the requirement.

2. The rotary drum is elevated at an angle of 2-2.5°at the feed end. The rotary drum screen machine adopts combined screen, which is installed on the drum that is welded on the main shaft. After the materials enter into the drum through the feed hopper, by the constant rotating of the drum, the materials are screened gradually through different screens. The fine particle passes through the screen and discharge through the outlet at the bottom, while the rough material flow forward along the slope of the cylinder and finally exits at the rear of the trommel screener.

3. Driving part. The motor drives the belt pulley, triangle belt and speed reducer, making the driving shaft rotate. This part adopts pin coupling, which makes it convenient for assembly and maintenance.

1. Adopt combined screen which is easy for maintenance and replacement.

2. High screening efficiency, reducing labor intensity.

3. The driving part adopts pin coupling, making it convenient for assembly and maintenance.

4. Reasonable structure, stable operation, no damage to the rotary machine.

5. Sealed dust cover is installed outside the rotary sieve, eliminating flying dust, improving the working environment.

6. The sealed dust cover also helps isolate the noise produced during operation.

7. Being used in organic & compound fertilizer production lines, behind fertilizer cooling machine.

Operation Instructions of Organic Fertilizer Sieving Machine

1. Rotary drum sifter should be started under no burden. It’s strictly forbidden to start the machine with materials in it to avoid damage.

2. Check all the bolts for their tightness before starting the machine.

3. Check whether the oil level in the bearing block and speed reducer is in place.

4. Start the main motor, and check whether the rotation direction is right. If opposite, stop the machine at once and adjust the direction.

5. Stop feeding materials before stopping the machine. It’s strictly forbidden to stop the machine with materials in it.

How to Lubricate the Compound Fertilizer Screening Machine?

1. Add gear oil to the speed reducer before using it, and replace the gear oil every four months.

2. Replace the grease in the bearing block every three months.

Technical Data of Fertilizer Rotary Screener

|

Model

|

Overall Dimensions L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Inclination(0)

|

|

FY-GTSF-1.0X3

|

3800x1300x2600

|

1-3

|

3

|

2-2.5

|

|

FY-GTSF-1.2X4

|

5000x1600x3000

|

2-5

|

5.5

|

2-2.5

|

|

FY-GTSF-1.5X5

|

6300x1880x3450

|

3-7

|

7.5

|

2-2.5

|

|

FY-GTSF-2.0X8

|

9800x2700x4700

|

11/15

|

2-2.5

|