Introduction of Double Helix Compost Windrow Turner

Double helix compost turners are used for making compost piles, fermenting and composting organic waste, such as animals & fowls manure, sludge

Function of Double Helix Compost Turner

1.Achieving the special requirements in composting process, such as raw materials crushing – shaping the stockpile or achieving quantitative

2. Regulating Stockpile Temperature. During windrow turner operation, organic materials are in close contact with a large volume of fresh air, which helps active aerobic microorganisms, and carries heat of fermentation which raises the pile temperature. With heat up, fresh air cool down the stockpile temperature, thus forming an alternating status of “moderate temperature-high temperature-moderate temperature-high temperature”. Various beneficial microorganisms are with rapid growing & multiplication.

3. Improving the stockpile permeability. This composting equipment can turn organic materials into small clumps, making dense stockpile be fluffy and elastic, forming suitable porosity.

4. Adjusting the stockpile moisture. The most suitable water content for materials fermentation is around 55%, and the moisture standard of finished organic fertilizer is below 20%. During fermentation, new moisture will be generated due to biochemical reaction, and raw materials consumption can also cause the loss of water. Thus, in organic fertilizer production, in addition to the moisture evaporation caused by heat conduction, during the process of turning organic materials, there will also be vapor emitting.

5. Agitating Function. In compost pile making and organic fertilizer production, subsidiary materials are added to adjust the carbon-nitrogen ratio, PH, and water content of raw materials. The compost turner machine stirs main materials with kinds of subsidiary materials which are stacked together in proportion, and mixes them evenly to achieve the purpose of quenching.

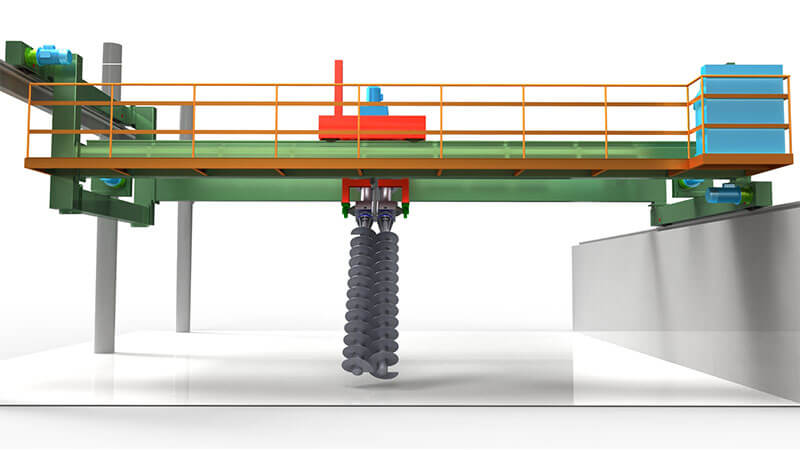

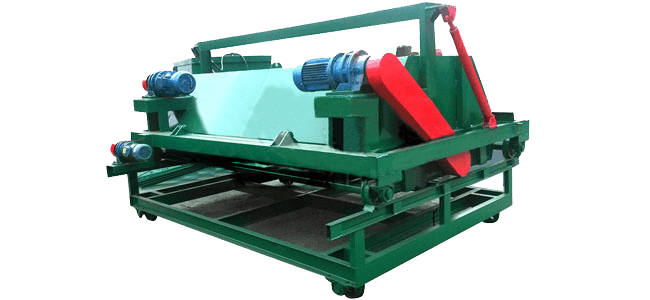

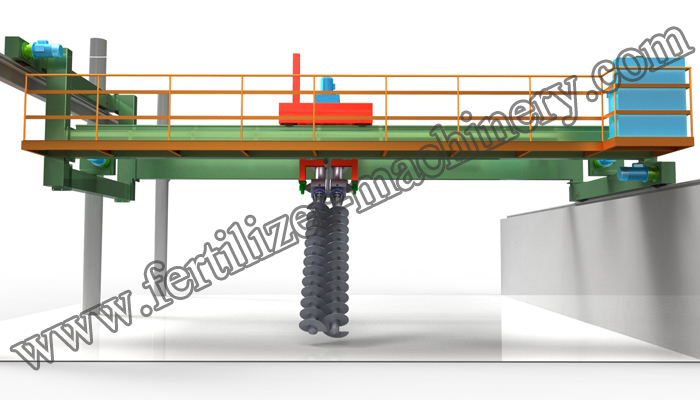

Structure of Double Helix Fertilizer Compost Machine

Double helix windrow turner is composed of walking device which can drive the fertilizer turner walking forward or backward, left or right, rotary vane lifting device, rotary vane power unit, and PLC control cabinet etc. This organic fertilizer turner overcomes deficiencies of common groove type compost turner, such as large operation area, small turning span, low fermentation depth etc. The highest composting height of our double helix fertilizer turner can be 1.7m, turning span being 6-11m, which greatly improves the utilization of the workplace.

It is specially used to ferment and turn low-organic materials, such as sludge, MSW and so on (as there is low organic matter content, fermentation depth should be deep enough to raise the fermentation temperature, thereby reducing the fermentation time). The double helix compost mixer turner utilizes two rotary vanes that intermesh with each other and rotate in the opposite direction to turn materials upside down. Simultaneously, it does lateral and vertical movement to help raw materials sufficiently contact with Oxygen in the air. Aerobic fermentation is formed. This compost turner is equipped with PLC programmable control cabinet, having manual or automatic control function. Remote control device can also be equipped to achieve precise operation.

Technical Data of Compost Windrow Turner

|

Model

|

Fermentation Groove Depth(mm)

|

Power(KW)

|

Fermentation Groove Span(mm)

|

Production Capacity (m³/h)

|

|

FY-SLXFDJ-325

|

1500-2100

|

26

|

6000-11000

|

200-280

|