Introduction of Groove Type Compost Turner Machine

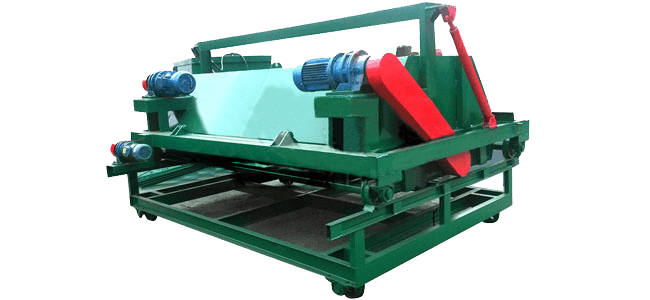

aerobic fermentation machine and compost turning equipment. It includes walking fermentation groove, walking track, power-pick device and other parts. The working portion of the compost turner machine adopts advanced roller drive. There are adjustable type and non-adjustable type for choice. The groove type compost windrow turner is widely used for dealing with animal manure, household garbage, sludge, crop stalks and other organic wastes, and also can be used in feed fermentation.

aerobic fermentation machine and compost turning equipment. It includes walking fermentation groove, walking track, power-pick device and other parts. The working portion of the compost turner machine adopts advanced roller drive. There are adjustable type and non-adjustable type for choice. The groove type compost windrow turner is widely used for dealing with animal manure, household garbage, sludge, crop stalks and other organic wastes, and also can be used in feed fermentation.Features of Fertilizer Compost Windrow Turner

2.The innovation point of this compost making machine is to take full advantage of underground space to design deep tank and adopt long-distance composting technology. It makes large-scale innocent treatment of organic waste in limited space come true.

3.It has a compact structure and advanced technology. It adopts unique groove type continuous aerobic fermentation technology to decompose, anhydrate, sterilize and deodorize organic waste and achieve innocent treatment, resourceful treatment and minimization treatment. Besides, it has advantages such as stable product quality and low energy consumption and so on.

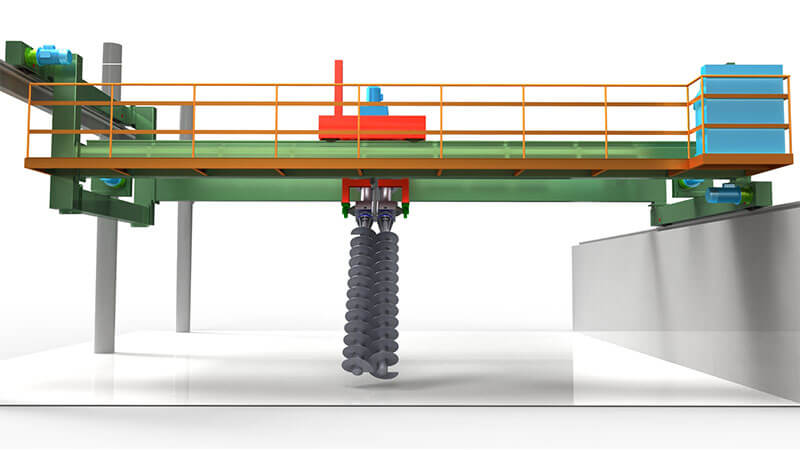

4.The groove type compost turning processing of the fermentative material is under intelligentialized auto-control. With the action of lengthways and sideways walking gear, fermentative material is turned over in the tank so that the aerobic fermentation can be completed well.

5.The electronic control system of the organic fertilizer compost windrow turner is advanced and reliable. It is easy to operate and equipped with remote control. After the main engine runs, turn spin button to “automatic”, the compost turner will start to work. When it sideways moves to one side, the compost turner will stop moving after touching the limit switch. The compost turner lengthways moves three to five seconds, then sideways moves to the opposite side. This cyclic process achieves the desired effect for compost turning and oxygenating.

5.The electronic control system of the organic fertilizer compost windrow turner is advanced and reliable. It is easy to operate and equipped with remote control. After the main engine runs, turn spin button to “automatic”, the compost turner will start to work. When it sideways moves to one side, the compost turner will stop moving after touching the limit switch. The compost turner lengthways moves three to five seconds, then sideways moves to the opposite side. This cyclic process achieves the desired effect for compost turning and oxygenating.As for the groove type hydraulic compost windrow turner, except for all features mentioned above, it is manufactured with an additional hydraulic pressure device, with advantages as follows:

● Hydraulic control system is adopted when manufacturing, by which the organic materials are turned up and down, and mixed with microbial agents more evenly. To some extent, it ensures that every detailed parts in the organic materials are fully contacted with air, hastening the decomposition speed.

● Electricity saving, and long service life. In some areas, the power shortage situation still hasn’t been eased, so customers are prone to choose a more electricity-saving compost turner. Then our groove type hydraulic organic fertilizer compost turner machine will be your best choice.

Working Principle of Organic Fertilizer Compost Windrow Turner

1.This organic fertilizer compost turner adopts an integrated structure which consists of reduction drive, material throwing device, walking wheels,

2.Under the operation of vertically and horizontally walking gear, the high-speed disc harrows throw the fermentative materials up, then fall to the ground and the material shift. The fermented material is carried away and the space is cleared for the material requiring fermentation. Thus a complete fermentation process is formed.

3.The electromotor of the organic fertilizer compost turner machine transfers the power to cycloidal pin wheel speed reducer then to the roller. The stirring blades in the roller are spiral so that the materials in the fermentation tank can be enough stirred and shifted which makes the materials fully catch air and the ferment effect will be better.

Technical Date of Groove Type Fermentation Machine

|

Model

|

FY-FJ6000×350

|

FY-FJ4000×1050

|

FY-FJ4000×350

|

|

|

Matched power(kw)

|

25.74

|

41.5

|

10

|

10

|

|

Working speed(m/h)

|

50

|

50

|

50

|

50

|

|

No-load speed(m/h)

|

100

|

100

|

100

|

100

|

|

Size of fermentation tank

(w×h )mm |

6000×1050

|

6000×350

|

4000×1050

|

4000×350

|

|

External dimension

(mm) L×W×H |

4670×3920×2740

|

4670×4800×3200

|

4670×3920×2740

|

4700×4800×3200

|

|

Lift height of gear(mm)

|

1400

|

1500

|

1400

|

1500

|

Technical Date of Hydraulic Groove Type Compost Turner

|

Model

|

FY-XSCSFD03

|

FY-XSCSFD04

|

|

Power(kw)

|

15.5

|

22.75

|

|

Working speed(m/h)

|

50

|

50

|

|

Size of fermentation tank(w*h )mm

|

3000×700

|

4000×900

|

|

Lift height of mixing gear(mm)

|

700-1000

|

800-1100

|

Watching Video of Groove Type Compost Turner: