Introduction of Semi-wet Materials Crusher

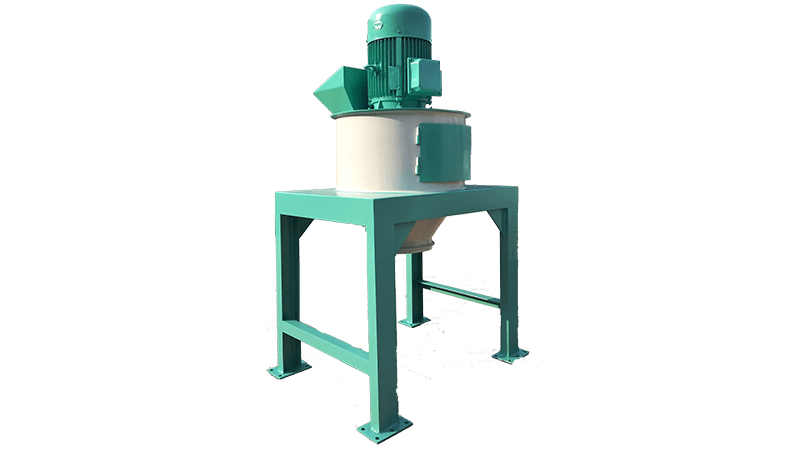

Our high-efficiency organic fertilizer crusher is a new reversible type crusher. It has a strong adaptability to the moisture content of the materials

This fertilizer crusher greatly shortens technological process, reduces equipment investment and saves operating cost, so it is the ideal machine for fertilizer production. Semi-wet materials crusher is the specialized crushing machine manufactured based on continuous research, improvement. It combines advanced technology at home and abroad, and completely solves the problem of crushing high moisture materials. It plays an important role in fertilizer production.

Working Principle of Fertilizer Crusher

After the crusher works, the organic material can be put into the crushing chamber through the feeding hole. The crushing system of the semi-wet materials crusher consisting of two-stage rotors crushes the organic materials in the crushing chamber in two stages. The organic material is first crushed

After the organic material is crushed enough, the granules are delivered to the discharging hole of the crusher. The semi-wet materials crusher has no screen hole so that various granules can come out from the bottom of the crusher directly without blocking.

Features of Organic Fertilizer Crushing Machine

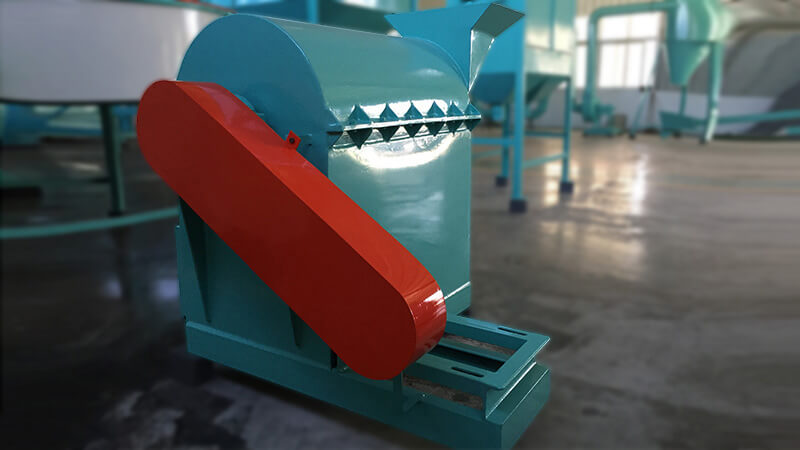

1.The rack of this fertilizer grinder is welded by high quality carbon steel plate and box iron. It passes strict production conformity certification & specific technological requirements.

2.The rotor of the fertilizer crushing machine adopts rational design & structure. With double-deck blades, its crushing efficiency is twice as much as other crushing machines. The materials enter the crushing part from the feeding hole, then are crushed into granules.

3.The inner lining plate is made of high strength material, with good abrasion resistance and durability.

4.Adopting flexible belt drive. The electric motor drives the belt sheave which transfers the power to the principal axis, making it rotate in a high speed to crush the materials.

5.The organic fertilizer crushing machine contains two layers of grinding systems to crush the materials finely and attain the optimum efficiency.

6.It adopts high-alloy hard-wearing hammers. The hammer slices are forged to promise they are strong and hard-wearing enough to prolong service life.

7.High technology is adopted to greatly ensure its safe reliability, maintenance-free and easy operation. It only needs one person to operate.

Application of Organic Fertilizer Grinder

The fertilizer crusher has a strong adaptability to the materials especially the matured waste and other materials with moisture content less than 30% and the crushing granularity meets the granulation requirement. Besides, the crushing granularity can be also adjusted according to customer demand.

It is mainly used to crush sludge, straw, biogas residue and other organic materials used for organic fertilizer production.

The crusher’s specific range of application includes

1.To crush the organic matters in the sludge

2.To crush the biogas residue in the biogas digester

3.To crush other organic materials applying to the crusher.

4.To deal with chicken manure, pig manure, cow dung fermentation.

5.To crush the municipal solid waste and grind the glass, broken ceramic and bricks in the waste.

Technical Data of High Moisture Materials Crusher

|

Model

|

FY-BSFS-40

|

FY-BSFS-60

|

FY-BSFS-90

|

FY-BSFS-110

|

|

Prod Capacity (t/h)

|

1-2

|

2-4

|

4-8

|

10-15

|

|

Particle size

|

0.5-5

|

0.5-5

|

0.5-5

|

0.5-5

|

|

Power ( kw)

|

22

|

30

|

30×2

|

45

|

|

Overall Dimension

L×W×H(mm)

|

1080X980X860

|

1480X1240X1260

|

1780X1660X1720

|

2160x2272x1880

|