Fertilizer Policies in Philippines

Philippines is a country dominated by agriculture and industry, whose agriculture contributes 20% of GDP and industry accounts for 30% of GDP. With the development of economy and the increase of the population, agriculture and industry of Philippines are developing in recent years. In the same time, waste produced from agriculture and industry are also increasing.

In recent years, sustainable development of economy and environment has been adopted by more and more countries. Philippine government has also recognized this reality and published some related policies. Fertilizer policies are issued by Philippine government, and have been an important component of Philippine agricultural policy now. More and more organic fertilizers are commercially produced and utilized, and organic fertilizer market is rapidly expanding in Philippines, which solves industry waste disposal problems and promotes the sustainable development of the economy.

Influence Factors of Organic Fertilizer Production in Philippines

A wide variety of materials can be used as organic fertilizers, such as animal manures, agricultural waste, industrial by-products, domestic wastes and

Besides the Philippine agricultural policy, there are other elements to promote the organic fertilizer market. Organic agriculture promotes Philippines’ organic fertilizer market, industrial by-products and municipal domestic waste supplies large amounts of raw materials for organic fertilizer.

1.Organic Agriculture

Organic agriculture, also called organic farming, is a new agricultural system that relies on organic fertilizer such as compost manure, green manure. With the support from Philippines government, organic agriculture has been widely applied in all cities. The development of organic agriculture solves a series problems of farming, such as the handing problem of agricultural waste, pollution of pesticides and decreased soil quality.

Rice and sugarcane are the main crops in Philippines. In 2015, nearly 15.7 million metric tons rice and 22.93 million metric tons sugarcane were produced. So many rice and sugarcane would produce lots of agricultural wastes such as rice husk, straw, sugarcane leaves and sugarcane press mud, which are all the important basic materials for organic fertilizer, and have been widely used in Philippines’ organic fertilizer market.

For one thing, organic agriculture boosts the demand for organic fertilizer, and pushes Philippines’ organic fertilizer market. For another, it also supplies large amounts of raw materials for organic fertilizer production.

2.Livestock and Animal Manure

Livestock is one of the top main contributors of the agriculture industry in Philippines. Animal manures such as chicken and pig manure are often regarded as waste, which can be converted and used in organic fertilizer market for crop production. Animal manures contain most elements required for plant growth including N, P, K and other trace elements. It has become the most commonly used basic materials of organic fertilizer, and can be easily sourced from dairies, farms, horse stables, etc.

3.Industrial Waste and By-products

The Philippines is primarily considered a newly industrialized country. In 2010, industry was responsible for 30% of Philippine’s GDP. Major industries are manufacturing include auto parts, textiles, food processing, shipping, medical products, toys, etc. Lots of industrial factories bring great economic benefit to Philippines, also produced various industrial wastes and by-products. However, most of these industrial by-products are widely used for organic fertilizer, and promotes Philippines’ organic fertilizer market.

There are three main industrial by-products widely used in Philippines’ organic fertilizer market.

◆Food processing industry waste

The Philippines Bureau of Food and Drugs Statistical Report of Establishments for 2006 lists a total number of 1,1601 food processing factories establishments nationwide. Wastes produced from these food processing factories are various, such as effluent from distilleries, milk factories, sugar refineries, fish canning plants, etc.

We mainly analyzes two types of industrial wastes from sugar industry and fish processing industry at this part.

As we all know, sugarcane is the main crop in Philippines, which provides lots of raw materials for sugar industry. In sugar production process, there are 3 main by-products produced: sugarcane leaves & bagasse, press mud and molasses. These sugarcane wastes are all rich in nitrogen(N), phosphorus(P), potassium(K), after composting fermentation, will become one new type organic fertilizer for sustainable agriculture.

Fish markets and fish processing industries such as canneries, fresh and frozen fish processing plants also play a major part in Philippines’ industry, and greatly promote the development of Philippines’ organic fertilizer market. In the fish processing, a large number of by-products, such as offal, skin, eye

◆Industrial waste water& residue

Organic fertilizer produced from industrial waste water/residue also accounts for a certain proportion in Philippines’ organic fertilizer market. Philippines’ industrial waste water and residue is mainly produced from automotive, distilleries, milk factories, textile factories and other manufacturing factories. However, the scope of organic fertilizer produced by industrial waste water is not suitable for all kinds of crops.

◆Biogas slurry and residue

Biogas slurry and residue is a kind of quality organic fertilizer that includes various treat elements, such as nitrogen, phosphorus, potassium, boron, copper, copper, iron, calcium,etc. Recovery of nitrogen, phosphorus and potassium in the

Municipal waste

Municipal waste is a serious problem in the development process of modern cities. Philippines is a rapid developing country, if the municipal waste can’t be handled properly, whose urban environmental quality and residents life quality will be seriously influenced.

Municipal waste mainly includes domestic wastes, kitchen garbage, river mud and pollution from sewage, etc. In recent years, the report founds that urban waste can be used as raw materials for organic fertilizer production. Composting is the preferred method of processing urban wastes for reuse. In Philippines, each year about 85% recyclable urban waste is transferred to treatment plant for organic fertilizer composting. Reuse of urban waste for organic fertilizer not only reduces environmental pollution, also offers raw materials for Philippines organic fertilizer market.

Philippines’ Urban Waste

How to make Organic Fertilizer in Philippines?

In the second part, we analyzes the factors affecting the organic fertilizer market in Philippines. At this part, we will introduce organic fertilizer production process.

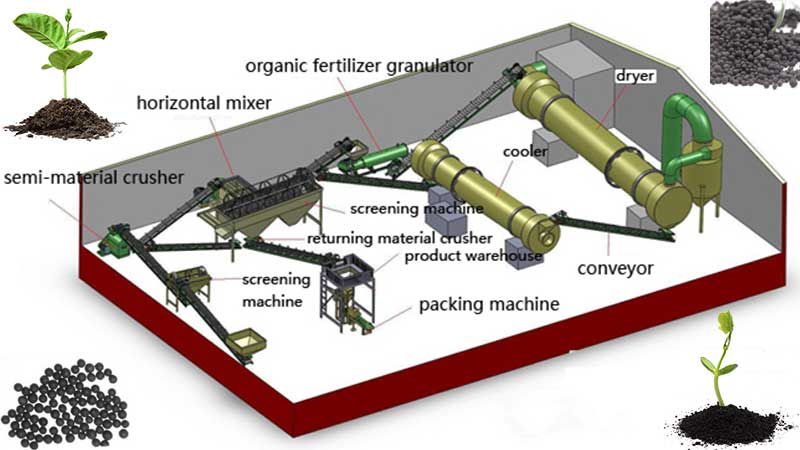

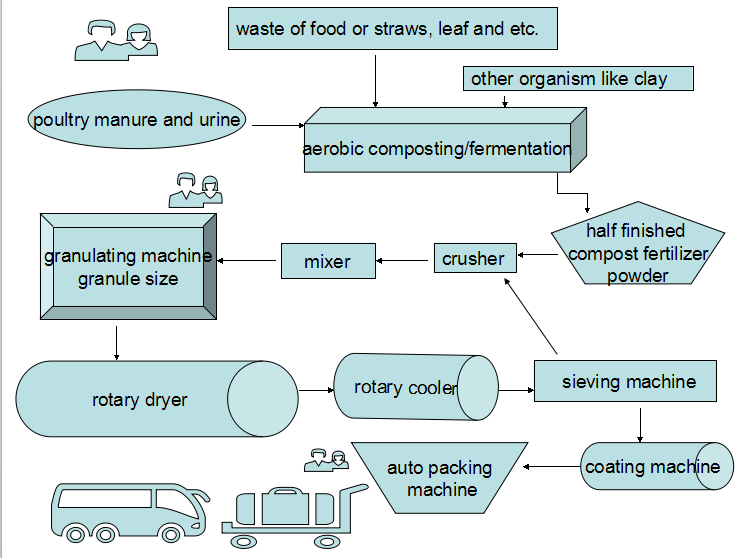

The organic fertilizer production mainly includes the following procedures: composting→fertilizer crushing→fertilizer mixing→fertilizer drying→fertilizer granulating→fertilizer cooling→fertilizer screening→fertilizer packing. However, all these steps can be finished once through our organic fertilizer production line.

Composting

Composting is an inexpensive, efficient and sustainable treatment for wastes. In Philippines, composting industry has been growing rapidly with the growing organic fertilizer market.

Composting is the indispensable step in organic fertilizer production line. Agricultural wastes such as rice straw, sugarcane bagasse and grass are widely

Fertilizer mixing & crushing

This two steps make fertilizer materials fully mixed together, improve the utilization of raw materials. Our machine applies to wet fertilizer materials such as straw, sludge, animal manures, waste water, etc.

Fertilizer Granulating

In Philippines’ organic fertilizer market, most of organic fertilizers are all formed through granulating, which is the most essential step in the organic fertilizer production line. Many types of organic fertilizer granulation machine such as disc granulator, rotary drum fertilizer granulator are the common machines used for organic fertilizer production.

Organic fertilizer processed by fertilizer granulation machine is easily absorbed agricultural crops, and meets the demands of organic fertilizer market in Philippines.

Fertilizer Drying

Fertilizer with too high humidity can’t be sold directly at organic fertilizer market in Philippines. This drying process can reduce the moisture of fertilizer to 20% through fertilizer rotary drying machine.

Fertilizer Cooling

Rotary drum cooler is widely used to cool fertilizer with certain temperature in organic fertilizer production line. It is applicable for cooling many types materials, such as organic fertilizer, compound fertilizer, industrial wastes and by-products, municipal waste, etc.

Fertilizer Screening & Packing

Fertilizer screening machine can achieve the fertilizer classification evenly. After screening, the processed fertilizer will be packing into bags by automatic weighing packing machine and sold at organic fertilizer market.