Nowadays, organic fertilizer usage is about 50% of the total fertilizer usage in Western countries. People pay much more attention to food safety in developed areas. The more organic food demands, the more organic fertilizer requires. According to developmental characteristics and market trends of organic fertilizer, there is a promising future for the organic fertilizer market.

For organic fertilizer production, there are many available raw materials.

1. Animal manure: chicken manure, pig manure, sheep manure, cow sang, horse manure, rabbit excrement, etc.

2. Industrial waste: vinasse, vinegar residue, cassava dregs, a sugar residue, biogas waste, furfural residue, etc.

3. Agricultural waste: crop straw, soybean meal, cottonseed meal, etc.

4. Household waste: kitchen waste

5. Sludge: municipal sludge, river sludge, filter mud, etc.

We provide a fertilizer production installation guide, organic fertilizer production process, and technology for you. For fertilizer investors or farmers, if you have little information about organic fertilizer production and have no mush source of customers, you can begin organic fertilizer production on a small scale. Therefore, a mini organic fertilizer production line is the best choice. The fertilizer production capacity ranges from 500 kg/h to 1 t/h. The article How to Start an Organic Fertilizer Production Line has a detailed introduction to a proposal for a new organic fertilizer plant construction.

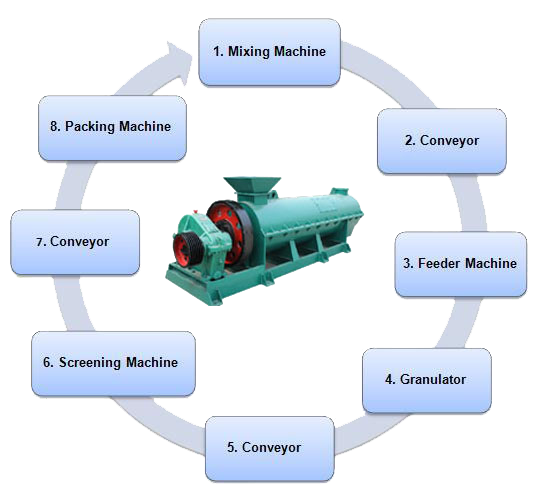

Fertilizer Machinery Needed in Mini Organic Fertilizer Production Line

1. Self-propelled Compost Turner – Model: 9FY-FYD-2000

When you make organic fertilizer, the first step is to make compost to make certain raw material decomposition. A self-propelled compost turner machine is widely used for compost making. Its main function is to turn and mix organic materials. Therefore, the fermentation process is accelerated and the whole compost takes only 7-15 days.

|

Model

|

Width of the pile(mm) |

Height of the pile(mm) |

Piles distance(m) |

Power(water-cooling, electrical start) |

Processing capacity(m³/h) |

Driving mode |

|

9FY-FYD-2000 |

2000

|

500-800

|

0.5-1

|

33FYHP

|

400-500 |

3 gears forward; |

2. Chain Crusher – Model: FY-LSFS-60

After fermentation, organic fertilizer raw materials need to be crushed, especially for sludge, biogas digester, animal manure, solid water, etc. This machine can crush organic matters that contain high water content to 25-30%.

|

Model

|

Overall Dimension

LXWXH (mm)

|

Production Capacity (t/h)

|

Motor Power (kw)

|

Maximum Size of Entering Granule (mm)

|

Size After Crushing (mm)

|

|

FY-LSFS-60

|

1000X730X1700

|

1-5

|

15

|

≤60

|

<Φ0.7

|

3. Horizontal Fertilizer Mixer-Model: FY-WSJB-70

Horizontal fertilizer mixers can blend organic fertilizer raw materials, feed, concentrated feed, additive premix, etc. In addition, it can be used for mixing of two more fertilizers. Even if the fertilizer materials have differences in gravity and size, it can reach to great mixing effect.

|

Model

|

Capacity(t/h)

|

Power(kW)

|

Overall Dimensions (L×W×H) (mm)

|

|

FY-WSJB-70

|

2-3

|

11

|

2330×1130×970

|

4. New Type Spherical Organic Fertilizer Granulator – Model: FY-JCZL-60

A new type of organic fertilizer granulator machine is used for the granulation of chicken manure, pig manure, cow dung, black carbon, pottery clay, and kaolin. etc. Fertilizer granules have high organic content, which can reach 100%. Particle size and uniformity can be adjusted according to the step-less speed adjustment function.

|

Model

|

Capacity(t/h)

|

Granulating ratio |

Motor Power(kW) |

Dimension L× W × H(mm) |

|

FY-JCZL-60

|

2-3

|

≥85%

|

37

|

3550×1430×980

|

5. Fertilizer Screening Machine – Model: FY-GTSF-1.2X4

A fertilizer screener is used to separate standard fertilizer granules from unqualified fertilizer pellets.

|

Model

|

Capacity (t/h) |

Power (kW) |

Inclination(0)

|

Dimension L× W × H(mm) |

|

FY-GTSF-1.2X4

|

2-5 |

5.5 |

2-2.5

|

5000×1600×3000

|

6. Fertilizer Packaging Machine-Model: FY-DGS-50F

You can use an automatic fertilizer packaging machine to pack organic fertilizer granules 2-50kg per bag.

|

Model

|

Power |

Voltage |

Air source |

Air source |

Packing |

Packing pace |

Packing |

Overall Dimensions

L×W×H(mm)

|

|

DGS-50F

|

1.5

|

380

|

1

|

0.4-0.6

|

5-50

|

3-8

|

±0.2-0.5%

|

820×1400×2300

|

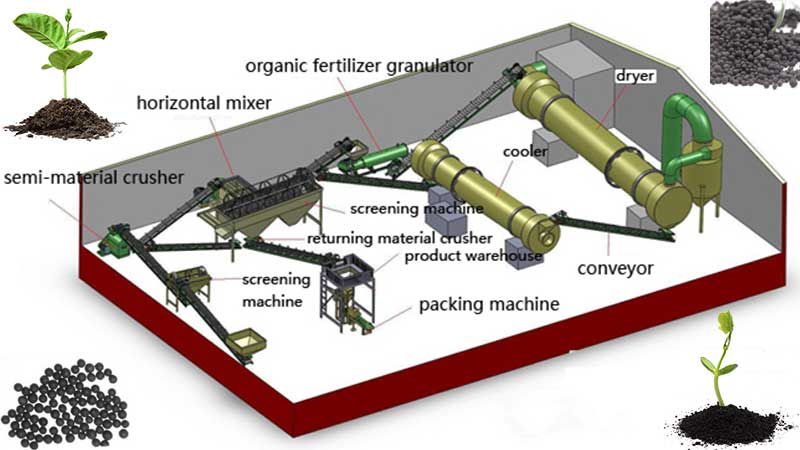

Workshop Layout of Small-Scale Organic Fertilizer Production Line