Vinasse is the main waste in liquor industry, which is in high productivity. Organic matter in vinasse has a characteristic of high concentration, far beyond the state-specified emission standards , becoming a major source of environmental pollution. Although it increases investment on treatment before

From the perspective of crop nutrients, organic fertilizer is the best choice for its growth. On the one hand, organic fertilizer has no side effect on crop growth. On the other hand, organic fertilizer enables increase crop yield. To make organic fertilizer with vinasse, it not only solves the problem of liquid industry, but also makes profit to these manufacturers. Using vinasse as raw material, it is environmental and efficient way to make organic fertilizer. To be specific, it uses solid content of vinasse after solid-liquid separation. After separation, the whole organic fertilizer production contains aerobic fermentation, mixing, crushing, granulation, screening, drying, cooling, coating and packaging.

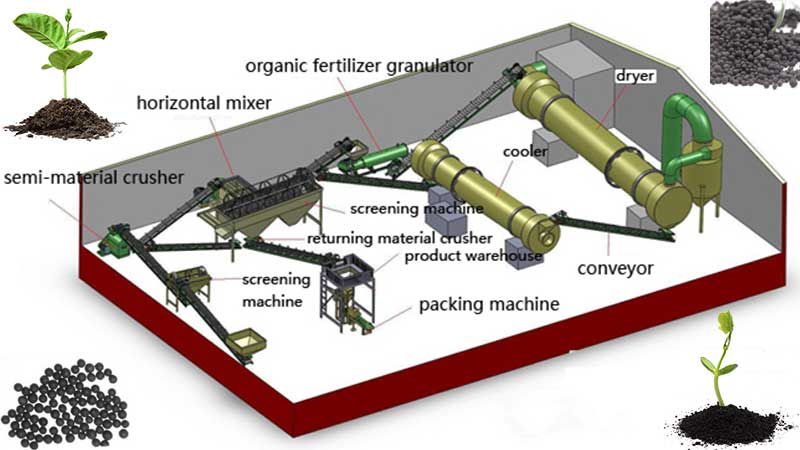

Vinasse Organic Fertilizer Manufacturing Process

Vinasse Solid-liquid Separation

Send the vinasse after wine production into the separation machinery in order to get the solid vinasse. With submerged pump or funnel, send material to dehydrator. The extrusion conveyor puts the vinasse to the front of the machine gradually. Simultaneously, make the water flow out of screen netting under the effect of filter press in material, improving the pressure in leading edge. Dehydrator is in continuous work so that materials are sent to the machine constantly. The pressure of leading edge is increasing steadily. When the pressure expands to a certain extent, discharge outlet is opening. The materials are squeezed out of extruder, realizing squeezing the material. If materials contain too much water, it will be pumped through discharge pipe to original pool. The waste water, separated by screw extractor, is sent to flow tank directly. In order to control the speed of the feed and water content,

Vinasse Fermentation

Add leavening agent to solid vinasse and pile it in septic tank after mixing. And then it can be in aerobic fermentation. Put the raw material of 1: 1 volume ratio on the ground or septic tank, stirring with a compost turner. Composting height is not less than 1 m and width not less than 2 meters. Turn the material every day. Use cellulose, degrading enzyme, protein or rhizopus as starter culture. Starter accounts for 1-10% of the total mixture. It takes up 6-15 days to ferment raw materials. Make temperature of fermentation between 50℃to 80℃. In addition, quicklime can be added so as to adjust power of hydrogen. Generally, keep pH value between 6 and 7.

Vinasse Mixing

Add 3% of ammonium sulfate, 6.6% of ammonium bicarbonate, 2% of calcium magnesium phosphate, 1% of potassium sulphate and 10% of humic acid. And then stir the mixture with fertilizer mixer.

Vinasse Crushing

After mixing raw materials, use fertilizer chain crusher to make mixed materials broken. According to characteristics of vinasse, this kind of fertilizer

Vinasse Organic Fertilizer Granulation

After crushing the materials. It can be granulated through fertilizer belt conveyor to new type organic fertilizer granulator. Because vinasse is semi moisture raw material, it is suitable to use this type organic fertilizer granulator. It makes use of the characteristics of growing particles under a certain force. The produced particles are strong, reducing energy consumption for drying. And then it can be screened directly.

Vinasse Organic Fertilizer Drying and Cooling

Primary feed is sent to drying system by belt conveyor. The chemical technology is applied while drying the feed. The water content should be less than 30% before drying. After drying, make the temperature of fertilizer cool down.

Vinasse Organic Fertilizer Packing

After sampling inspection, send the up-to-standard products to packaging system. According to packing specification, package and seal the products by automatic fertilizer packaging machine. And then deliver finished products to finished goods warehouse.

Characteristics of Vinasse Organic Fertilizer

1.Improving soil physical property

It makes soil soft and farming easy, improves soil granular structure, increases soil porosity and hasten root mass growth. In addition, it increases water retaining capacity and fertilizer preservation, reducing leaching loss.

2. Pest and disease damage suppression

It can produce various enzyme. The enzyme has important effect on different disease, including replant disease, root-knot nematode, wilt, bacterial wilt and epidemic disease, etc.

3. Improving fertilizer efficiency

The organic fertilizer has no side effects. It is environment friendly, which is safe to crops and soil. Combining with inorganic fertilizer, it can increase fertilizer efficiency. What’s more, it is cost-saving for farmers.

4. Providing nutrients for crops

Efficient beneficial microbial flora is in continuous activity, which can activate the air of nitrogen, release insoluble phosphorus and potassium. On the other hand, it can add soil organic matter and release needed nutrients for crop growth.

5.Promoting root growth

The large reproduction of beneficial microorganisms secretes hormones and polysaccharide to external, inhibiting the growth of pathogenic bacteria, promoting the spread of root system and reducing the occurrence of various diseases.