Organic Waste: The Problem? The Opportunity? The Solution?

Problem existed:

with the growing population, urbanization, and industrialization, more trash is being produced, being a constant threat to the environment and health safety. There exists a humongous problem of solid waste management being faced by the entire world. Everyday waste is a mix of organic and inorganic stuff and if not managed and disposed of properly, poses monetary and social ramifications.

Entrepreneurs see a business opportunity in organic waste–Organic waste can be treated to make compost and soil conditioning products.

The availability of huge amounts of organic solid wastes is the greatest opportunity for the implementation of composting. The other opportunities include the huge demand for compost by farmers, an increase in the price of chemical fertilizer, and the environmental impact of landfilling.

Solution:

All clean source-separated organic waste could be converted to powder organic fertilizer (compost fertilizer) for on-farm and garden use through modern composting technology, such as open windrow or tunnel composting, and in-vessel composting. Composting does solve the problem of waste disposal to some extent and is the key to a clean, trash-free world. Among the various treatments for managing organic waste such as the use of landfill and incineration, decaying organic wastes by using biological processes is considered as a more suitable solution method.

Recommendations are mainly addressed to throughput capacities, which can be summarized below:

◆ Small-scale, low-tech composting plants with a capacity of up to 50 t/d (from a few hundred t/y up to some thousand t/y);

◆ Medium-to-large composting plants with a capacity ranging from 50 to 600 t/d (approximately 15,000 to 185,000 t/y);

◆ Large MBT plants with a capacity of 1,250-2,500 t/d (387,000 – 775,000 t/y)

Raw Materials – Common Composting Inputs

The range of input materials for composting is almost endless.

◇ Cattle manure, poultry manure, horse manure, pig manure, and other manures (e.g. sheep, rabbits, goats, etc)

◇ Agriculture wastes, straw, sawdust/shavings, woodchips, bark, grass clippings, crop residues, wood ash, spoiled hay, and silage

◇ Newspaper, cardboard, waste paper, biosolids, recycled compost, shrub, tree trimmings and leaves, household food organics, vegetables, food processing, vegetable wastes

◇ Freezing works waste, animal mortalities, fish processing, sea/aquatic weed, paper mill sludge, fertilizer/lime

Small Scale Powder Organic Fertilizer Composting Plant Setup

The composting process provides technical guidelines to local authorities, plant suppliers, and plant managers in order to help them manage the organic waste fraction in a proper way both from processing as well as from an environmental protection point of view.

Powder organic fertilizer composting systems are often described in terms of the complete process from the reception of organic raw materials through to the handling of the end product.

- Pre-processing of organic wastes

The goals of pre-processing include reducing the size of the brush, creating a homogeneous mix, and ensuring that compost mixes have acceptable C:N ratios and moisture levels.

All systems aim to control and/or optimize compost production by manipulating temperature, oxygen, and moisture during composting. Another important control over compost quality is achieved by the selection, pre-treatment and proper mixture of ingredients based on the ratio of carbon to nitrogen (C: N ratio) in the input materials prior to composting.

◇ Removal of any rubbish contaminating the feedstock.

◇ It may require chipping or grinding by an organic waste crusher machine if mixed with compostable products like green wastes, food wastes, agriculture wastes, etc.

◇ Mixing of shredded raw material with a bucket loader: Management of the composting process initially requires the proper mixture of ingredients based on the ratio of carbon to nitrogen (C: N ratio) in the input materials. In windrow composting a mixture of raw organic material is placed in elongated trapezoidal piles called windrows, and then repeatedly turned by a compost turner before being placed in the biological phase area.

◇ Bulking agents: A bulking agent is a carbon-rich material added to a compost mix to enhance airflow or convection through the windrow. Commonly used materials include wood chips, leaves, sawdust, cornstalks, or straw.

- Composting process

There are many widely-used composting systems, such as in-vessel composting, in-channel composting, windrow composting, etc. Here We will introduce in-channel composting technology and a windrow composting system.

In-Channel (Tunnel) Composting Process:

Organic waste in-channel composting systems are normally constructed inside buildings and are essentially a variant of the turned windrow system.

Channel Design: The material to be treated (usually animal manure: cow dung, chicken manure, horse manure, pig manure etc.) is placed between 2 long parallel walls, whereas in most cases the facility is housed inside a building. The walls vary in height from 1-3m (for the same reasons that windrows are normally constructed to that height) with a distance of approximately 6m apart from each wall, whereas the piles are about 50m long. Wood chips are used as a bulking agent with straw added to the manure as a carbon source.

The compost moves along the channel during turning. Turning aerates the material, and additional aeration may be provided by a forced air system on the floor of the bed. The composting phases may last 6-8 weeks, or 3 weeks with a 6-month maturing in static piles.

Application of In-channel composting system: The City of Guelph, Ontario, operates a materials recovery facility, which includes a composting system made by Longwood Manufacturing Corp. This is an in-channel system, which uses a turner made by Transform Systems. The feedstock is composted in-channel for 4 weeks, followed by covered windrows.

Working Video of in-channel composting:

Windrow Composting Process:

Windrow Composting Process:

Windrow composting is the most common composting method. It requires minimal infrastructure and has low installation and operating costs compared to many other composting methods.

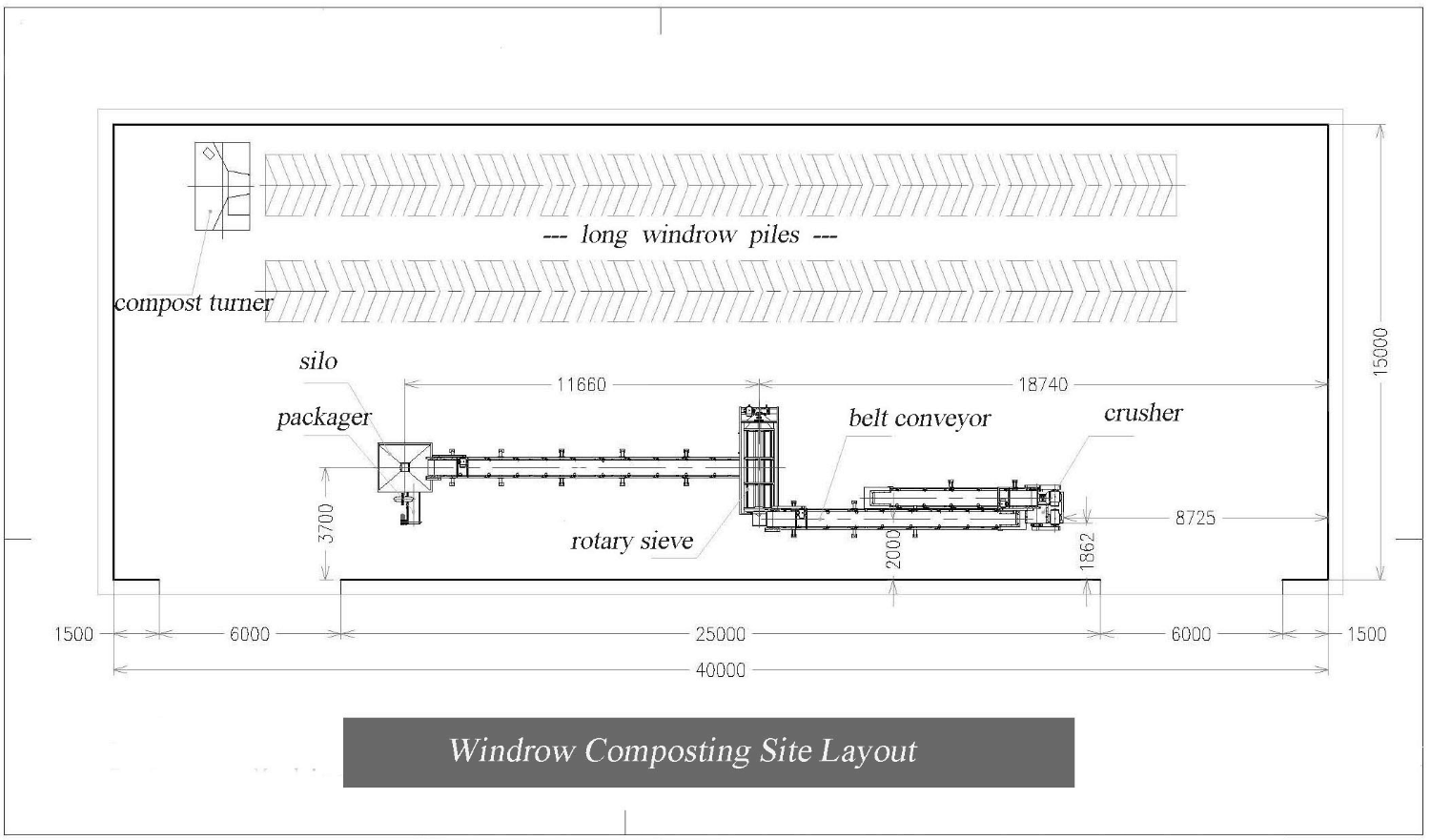

Composting plant design:

Composting plant design:

◇ Daily Output: 10-30 Tons

◇ Land area: 100m (L) × 50m (W)

◇ Raw material: all kinds of compostable organic wastes, such as animal waste, agricultural waste, etc.

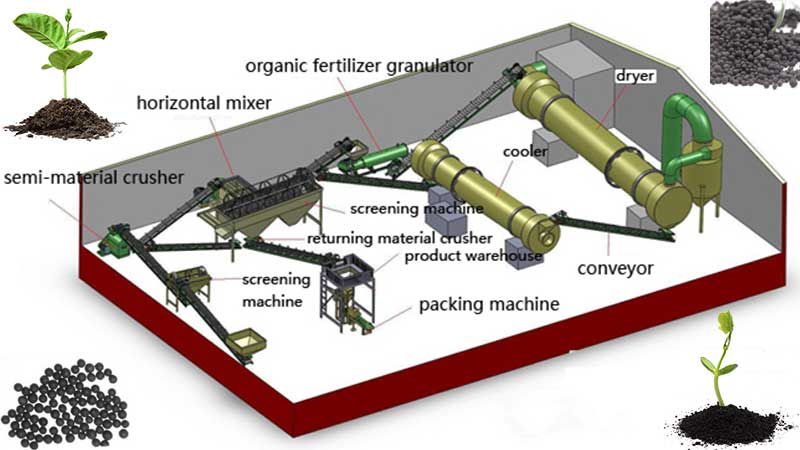

◇ Details comprising of compost production machinery: compost turner–compost crusher–generated compost sieve–finished compost packager

Composting process: organic wastes are placed into long, low windrows that are regularly turned using a full hydraulic compost turner which is used to control temperature 55℃, pH 5.5-8.5, and moisture content 40%-60%.

The turning process re-establishes the free air space in the material, mixes it, and re-introduces oxygen into the windrow. Composting facilities are able to dramatically vary windrow size, turning frequency, and how space at the site is used.

- Post-Processing

Post-processing practices involve the various stages that are employed in order to refine the produced compost and to meet market and regulatory standards.

Screening (if required) and wind sifting guarantee compost with homogenous particle size and free of contraries.