There are many sheep farms in Australia, New Zealand, America, England, France and Canada. Of course, it produces a great many of sheep manures. They are good raw materials for organic fertilizer production. Why? The quality of sheep manure is the first in animal husbandry. Sheep’s forage selection is buds, tender grass, flowers and green leaves, which are nitrogen concentration parts. The fresh sheep manure contains 0.46% of phosphorus

and 0.23% of potassium, but the nitrogen content is of 0.66%. Its phosphorus and potassium content are same with other animal manure. Organic matter content is up to about 30%, far beyond the other animal manure. Nitrogen content is more than double the content in cow dung. Therefore, when applied the same amount of sheep manure to soil, fertilizer efficiency is much higher than other animal manure. Its fertilizer effect is quick and is suitable for top dressing, but after decomposed fermentation or granulation, otherwise it easy to burn seedlings.

and 0.23% of potassium, but the nitrogen content is of 0.66%. Its phosphorus and potassium content are same with other animal manure. Organic matter content is up to about 30%, far beyond the other animal manure. Nitrogen content is more than double the content in cow dung. Therefore, when applied the same amount of sheep manure to soil, fertilizer efficiency is much higher than other animal manure. Its fertilizer effect is quick and is suitable for top dressing, but after decomposed fermentation or granulation, otherwise it easy to burn seedlings.Sheep is a ruminant, but rarely drinking water, so the sheep manure is dry and fine. The amount of feces is also very small. Sheep manure, as a hot fertilizer, is one of animal manures between horse manure and cow dung. Sheep manure contains relatively rich nutrients. It is both easy to break down into effective nutrients that can be absorbed, but also have nutrients difficult to decompose. Therefore, sheep manure organic fertilizer is a combination of quick-acting and low-acting fertilizer, suitable for a variety of soil application. Sheep manure by bio-fertilizer fermentation bacteria composting fermentation, and after the smashing of straw, biological complex bacteria stir evenly, and then by aerobic, anaerobic fermentation to become efficient organic fertilizer.

The content of organic matter in sheep waste was 24% ~ 27%, the nitrogen content was 0.7% ~ 0.8%, the content of phosphorus was 0.45% ~ 0.6%, the content of potassium was 0.3% ~ 0.6%, the content of organic matter in sheep 5%, nitrogen content of 1.3% to 1.4%, very little phosphorus, potassium is very rich, up to 2.1% to 2.3%.

Sheep Manure Composting/Fermentation Process

1. Mix sheep manure and a bit of straw powder. The amount of straw powder depends on sheep manure water content. The general composting/fermentation requires 45% of water content, that is, when you hand the manure into a group, there is water between fingers, but not

2. Add 3 kg of biological complex bacteria to 1 ton of sheep manure material or 1.5 ton of fresh sheep manure. After diluting the bacteria by 1: 300 ratio, you can evenly spray into the sheep manure materials pile. Add appropriate amount of cornmeal, corn straw, dry grass, etc.

3. It will be equipped with a good fertilizer mixer to stir the organic materials. Mixing must be uniform, not leaving the block.

4. After mixing all the raw materials, you can make windrow compost pile. The pile width is 2.0-3.0 m, height of 1.5-2.0 m. As for length, more than 5 m is better. When the temperature is over 55℃, you can use compost windrow turner to turn it.

Notice: there are some factors that are related to your sheep manure composting making, like temperature, C/N ratio, pH value, oxygen and validation, etc. See more at 5 Factors Affecting Your Organic Fertilizers Quality

5. The compost will be 3 days heating, 5 days odorless, 9 days loose, 12 days fragrant, 15 days into decomposition.

a. On the third day, compost pile temperature rises to 60 ℃ -80 ℃, killing E. coli, eggs and other plant diseases and insect pests.

b. On the fifth day, the smell of sheep manure is eliminated.

c. On the ninth day, composting becomes loose and dry, covered with white hyphae.

d. On the first twelfth day, it produces a wine flavor;

e. On the fifteenth day, the sheep manure becomes mature.

When you make decomposed sheep manure composting, you can sell it or apply it in your garden, farm, orchard, etc. If you want to make organic fertilizer granules or particles, the compost manure should be in deep organic fertilizer production.

Sheep Manure Commercial Organic Granules Production

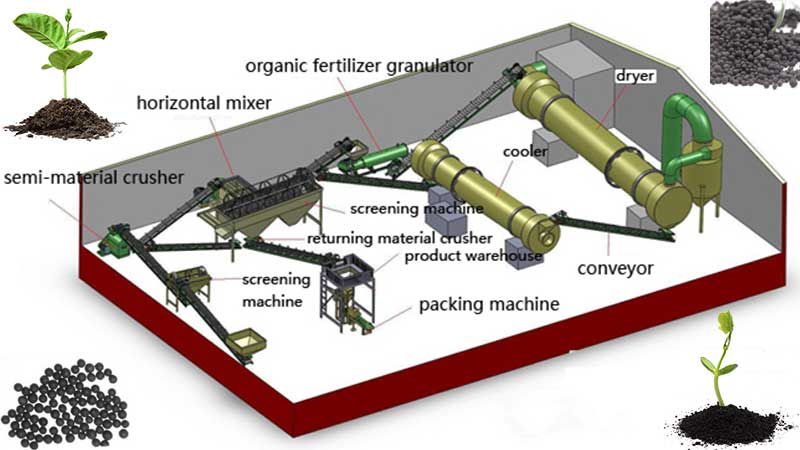

After composting, the organic fertilizer raw materials are sent into the semi-wet material crusher to crush. And then add other elements to composting (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) to meet the required nutrient standards, and then mix the materials. Use new type organic fertilizer granulator to granulate the particles. Dry and cool down the particles. Use screener machine to make classify standard and unqualified granules. Qualified products can be packed and unqualified granules return granulator for re-granulation.

The whole sheep manure organic fertilizer production process can be divided to composting-crushing-mixing-granulating-drying-cooling-screening-packaing.

There is different kind of organic fertilizer production line (small to large scale) for your choice.

Sheep Manure Organic Fertilizer Application

1. Sheep manure organic fertilizer decomposition is slow, so it is suitable for the base fertilizer. It has increase yield effect on crops. It would be better with combination of hot organic fertilizer. Applied to the sandy and too sticky soil, it can achieve fertility improvement, but also improve soil enzyme activity.

2. Organic fertilizer contains various nutrients required to improve the quality of agricultural products, to maintain nutritional requirements.

3. Organic fertilizer is benefit for soil metabolism, improving soil biological activity, structure and nutrients.

4. It enhances crop drought resistance, cold resistance, desalination and salt resistance and disease resistance.