Introduction of Double Mode Fertilizer Granulation Machine

Working Principle of Organic Fertilizer Pellet Mill

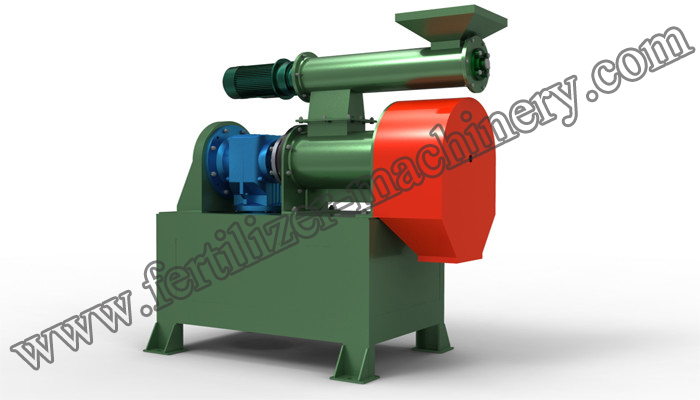

Applying dual-die (ring die and flat die) granulation & bilateral extrusion technology, organic materials obtain continuous and fast extruding, significantly strengthening physical pelletization pressure between particle substances. Granulation efficiency increases by 1-3 times compared with conventional

Features of Double-mode Organic Fertilizer Granulator

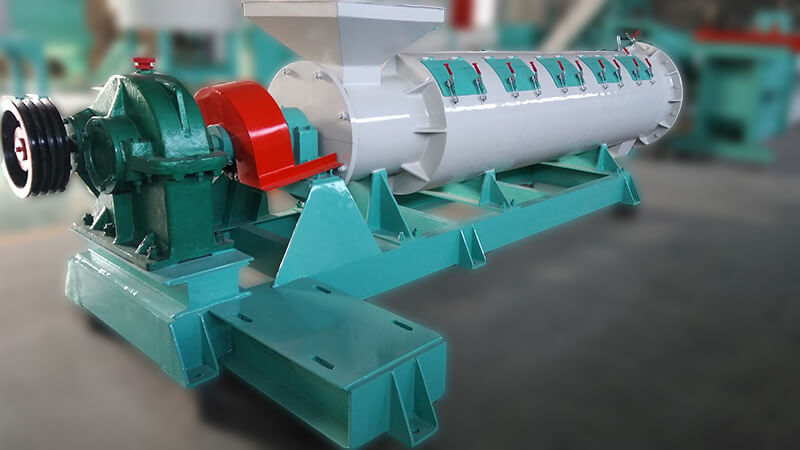

Dual-mode organic fertilizer granulation machine includes Feeder, Granulator, and Control System. The feeder is installed over the granulator. It consists of hopper, screw conveyor (or auger conveyor, PID control quantitative feeding), and variable-frequency motor. The top side of the auger conveyor is connected with hopper, the other side with discharge opening. The PID controlled screw conveyor is driven by variable-frequency motor.

The granulator consists of main motor, reducer, pressure-transport auger conveyor, radial pressing roll, axial pressing roller, ring die and flat die. The output shaft of granulator main motor joins with the reducer. Coupling connects reducer output shaft with main axle of pressure-transport auger conveyor. On the top end of screw conveyor, there is feed opening linking with discharge opining of the feeder. On the other end, there are radial and axial pressing rollers, the outside of which are respectively established

The control system mainly consists of current transformer, intelligent transmission ammeter, and frequency converter. Load current output of granulator main motor is passed through current transformer, whose electrical signal output terminal is linked with input terminal of current transmission signal of frequency converter. Power supply output side of frequency converter connects with power source input terminal of frequency motor.

Application of Organic Fertilizer Granulator

The double-mode organic fertilizer pellet mill is with simple structure, high output, low power consumption, and less wear. It has both screw extrusion technology and ring die & flat die granulation technique. It can be widely used in chemical, bio-energy, food, feed, fertilizer, and other industries. This fertilizer pellet mil is also suitable for producing organic fertilizer, bio-fertilizer, organic-inorganic compound fertilizer with raw materials being organic wastes from enterprises, such as filter mud, sugar, alcohol, starch, and animal husbandry.

Technical Data of Organic Fertilizer Granulator

|

Model

|

Dimension(mm)

|

Production Capacity(t/h)

|

Power(kw)

|

|

FY-SMZL-40

|

1760x960x1850

|

3-7

|

30

|

|

FY-SMZL-60

|

2130x1000x2380

|

5-10

|

45

|