Introduction to Rotary Drum Fertilizer Granulator

Rotary drum granulator is one of the key equipment in the compound fertilizer industry. The machine can make raw materials into ball shape particles,

Rotary Drum Fertilizer Granulator Features

1.Lining with pvc plastic plate or stainless steel plate, the material is not easy to stick to the rotary drum.

2. The granules produced by the rotary granulator have high strength and good appearance.

3. Anti-corrosion and wear resistant, long service life, easy operation and maintenance.

4. High fertilizer granulation rate which can reach 70%, less returning fertilizer created which have small size. The returning fertilizer can be regranulated.

How does Fertilizer Drum Granulator Work?

The raw materials enter into the rotary drum granulator by the belt conevyor. With the constant rotating of drum, the materials form a rolling bed, and moves along a certain path. Under the extrusion force produced, the materials agglomerate into small particles, which become the core, attaching the powder around to form the qualified spherical granules. The rotary drum is placed obliquely, the granules formed flow out through the outlet of the granulator. The shovelling plates inside the drum help granulating and cleaning– the whole production process of compound fertilizer (100,000 tons per year)

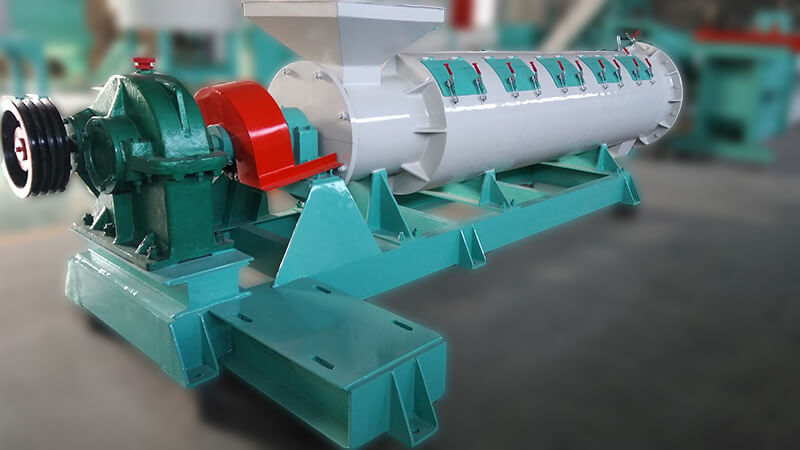

Rotary Drum Granulator Structures

| 1. The Bracket The bracket supports the whole rotating part of the granulator and bears great force. It is welded by medium steel carbon plate and channel steel. The riding wheel on the bracket will have great friction with the rolling belt. We adopt high quality anti-corrosion and wear-resistant material for the riding wheel, greatly prolonging the service life of the rotary granulator. |

|

3.The Gear The gear fixed on the machine body engages with the pinion on the main shaft, driving the machine work. The gear adopts high-tech wear-resistant material, which extends the service life of the drum granulator. 4. Rolling Belt The rolling belt fixed on the machine supports the whole body of the rotary drum granulator. |

| 2. Driving Part The driving part of the fertilizer drum granulator drives the machine to work and thus is very important.The main motor drives the belt pulley,triangle belt and speed reducer, and transmits to the main shaft, making the granulator work. Themain motor and speed reducer are both ISO National Free-inspection Product. |

|

5. Machine Body Machine body is the most important part of the rotary drum fertilizer granulator. It is welded by high quality medium carbon steel plate. PVC plastic plate or stainless steel plate is lined within the machine body having the function of anti-corrosion. |

Technical Data of Rotary Drum Fertilizer Granulator

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Inclination (0)

|

|

FY-ZGZL-12X40

|

4000x2200x1450

|

1-3

|

7.5

|

2–2.5

|

|

FY-ZGZL-15X60

|

6000x2600x2000

|

3-5

|

11

|

2–2.5

|

|

FY-ZGZL-18X70

|

7000x3100x2850

|

6-9

|

15

|

2–2.5

|

|

FY-ZGZL-22X80

|

8000x4300x3700

|

45/37kw

|

2–2.5

|