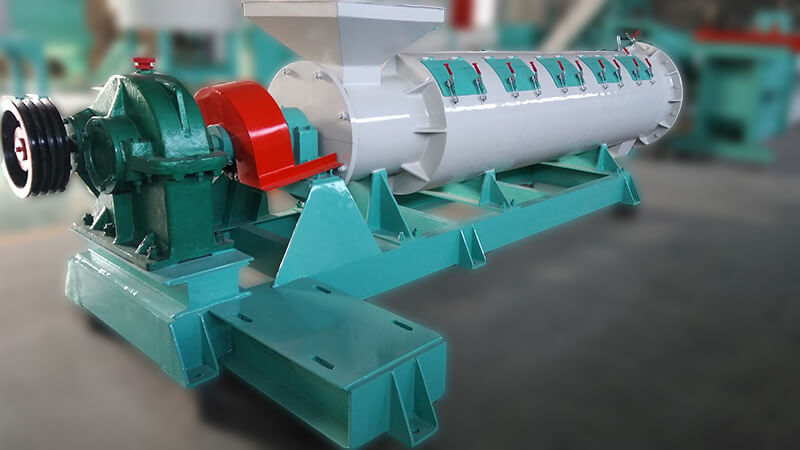

Flat Die Fertilizer Pellet Machine Description

Multifunction flat die fertilizer granule machine is aiming at producing bio-organic fertilizer. It is used for granulating various of organic matter after

Organic Fertilizer Granulator Advantages

1.Roller and flat die are made from precise material of alloy metal, wear-resistant and not easy to break.

2. Simple operation, easy maintenance and perfect technical design with less labor.

3. There is no need to use the binders when granulating for that organic particles can be inlaid with each other under certain conditions.

4. Granules shape of organic fertilizer is cylindrical. The content of organic fertilizer can reach up to 100%, achieving the pure organic substance granulation.

5. This fertilizer granulator machine adopts the pinch roller and the ends of the roller have the same wire speed with both the inner and outer of the mold. Thus, it avoids the friction between the die and roller which reduces kinetic energy loss and production expenses, and prolongs service life of the mold.

6. With features of compact structure of pinch roller, the machine runs smoothly. Meanwhile, the suppressing zone is increasing which improves the production efficiency.

7. Adopting the structure of screw center and pressure regulating , the internal distances between dies can change flexibly. And the diameter of the dies can range from 1.5mm to 20mm, thus it is suitable for various of raw materials. Meanwhile, it ensures the quality of organic fertilizer granules, and achieves the optimal benefit.

8. The finished products are firm. It can be screened directly by fertilizer screener after granulation. There is no need to dry the organic matters after fermentation, and the moisture of raw materials should be at 20%-40%.

|

|

|

|

How Does the Flat Die Organic Fertilizer Granule Machine Work?

Flat die fertilizer granulator machine is based on circular motion, and driven by motor. Under the action of friction, the press roll rotates. Temperature raises between the friction of press roll and materials. Under high temperature conditions, due to the process of roll extrusion, materials are extruded from the die, which forms organic fertilizers.

Organic Fertilizer Granulator Machine Applications

It is typically applied to granulate crude fiber materials, such as sawdust, rice husk, cotton stalks, cottonseed skins, weeds, other crops straw and plant waste. It is usually used in biological bacterial fertilizer, bio-fertilizer and organic fertilizer production.

Flat Die Organic Fertilizer Pellet Machine Technical Data

|

Model

|

Overall Dimension

LxWxH (mm)

|

Production Capacity (t/h)

|

Power (kw)

|

Granulation Rate (%)

|

Particle Temperature (℃)

|

Particle Diameter (mm)

|

|

FY-KP-40

|

1200x650x1450

|

0.75-2

|

15

|

>95

|

<30

|

3-30

|

|

FY-KP-60

|

1800x900x1850

|

1-3

|

22

|

>95

|

<30

|

3-30

|