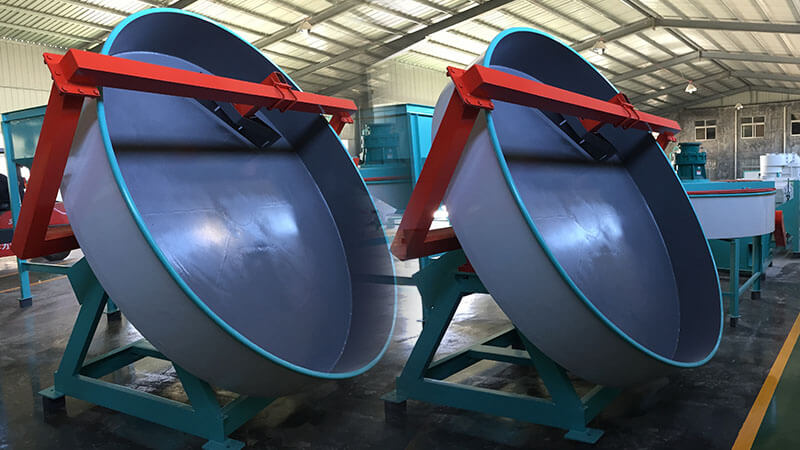

Disc Fertilizer Granulating Equipment Introduction

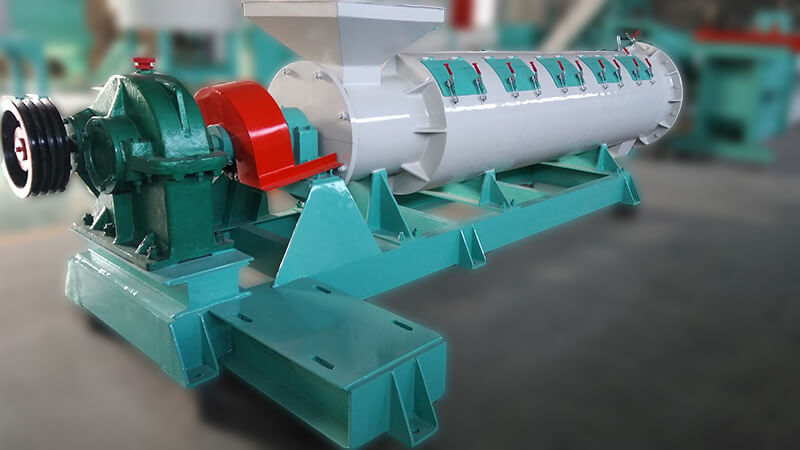

Disc Pan Fertilizer Granulator Machine Working Principle

Various dry powder materials are added from the top of the equipment, then being degassed, compressed and transported to arc shaped notch of those two rolls which are doing reversed rotation at a constant speed. Materials are condensed in the disc, reducing the stress-tolerant of materials which naturally separate with each other with the aid of gravity and surface tension.

High-output Disc Pan Fertilizer Pellet Mill Features

1. It is equipped with three discharge ports, more convenient for efficiently continuous fertilizer production, greatly reducing the labor intensity and improving labor efficiency.

2. The clearing device is equipped with automatic material clearing plate to remove the sticking materials, which greatly improves service life of machine and saves labor.

3. Rational structure, simple operation, convenient maintenance and stable performance, light weight, height reducing, flexible granulating position and

4. Reducer and motor use the flexible belt drive, in order to make sure starts steadily, and slow down the impact force. Thus, it will increase the service life of machine. Drive part adopts high-frequency quenching, which doubles the service life of machine.

5. Unique unpowered knives lowers down power consumption. Large discs consist of disc body and disc joints, and the disc joints can be accommodated upwards and downwards.

6. Rack section and regulation section are made of welded steel plate and channel which is anti-corrosion and durable.

7.The plate bottom adopts multiple radiation steel plates to reinforce, which is sturdy and durable, and never deformation.

Pan Fertilizer Pelletizer Structure

Pan fertilizer pellet machine consists of a large disc, big gear wheel, transmission part, rack, pedestal, scraper block, and unpowered scraper.

● Main body of disc granulator includes rack, regulation section, and the disc.

● A set of main gear reducer, input shaft is equipped with a belt pulley, while the output shaft is with a pinion.

● A set of main motor is fitted with a belt pulley.

● The device for supporting the disc includes a main shaft, two sets of roller bearing, and two bearing blocks.

Disc Pan Fertilizer Granulation Equipment Application

Disc fertilizer granulator is the main equipment to make the round granules. It is mainly used in organic fertilizer industry by using materials with livestock and poultry manure,

grass meal, and so on.Pan fertilizer granulator is widely applied in coal dust industry,

cement industry, iron and steel industry and the chemical fertilizer industry.

Pan Granulator Technical Date

|

Model

|

Disc diameter (mm)

|

Disc edge height (mm)

|

Speed (r/min)

|

Dip angle

|

Electronic power (kw)

|

Throughput (t/h)

|

|

ZL5

|

500

|

160

|

35

|

30°-60°

|

0.75

|

0.2

|

|

ZL10

|

1000

|

200

|

32

|

30°-60°

|

1.1

|

0.6

|

|

ZL15

|

1500

|

300

|

20

|

40°-55°

|

3

|

0.8-1

|

|

ZL20

|

2000

|

350

|

16

|

40°-55°

|

4

|

1-2

|