Our pan granulator bio-organic fertilizer production line could offer production of 20,000 tons/yer. It is proven by our customers that the whole organic fertilizer production process is centralized controlled, and all equipped fertilizer machines are highly automatic and easier to operate. The whole bio fertilizer plant is designed based on advanced and mature technologies. The fermentation system (compost windrow turner) can simultaneously make the best use of solar energy, bio-energy, and mechanical energy, greatly saving energy. The packaging system are controlled by the computer, ensuring the precision of finished products packing. The pan granulator bio fertilizer production line is suitable for organic materials, such as livestock and poultry manure, dregs, papermaking sludge, and municipal solid waste.

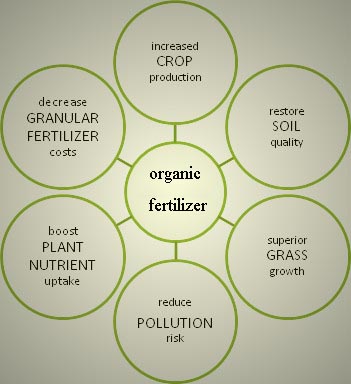

Benefits of Organic Fertilizer

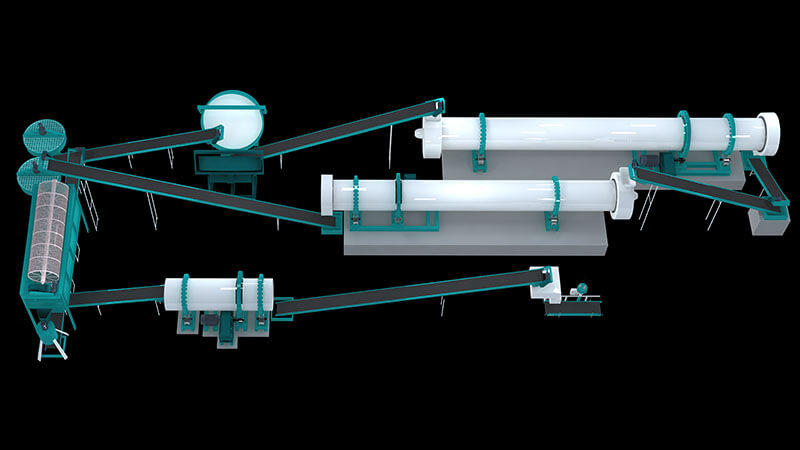

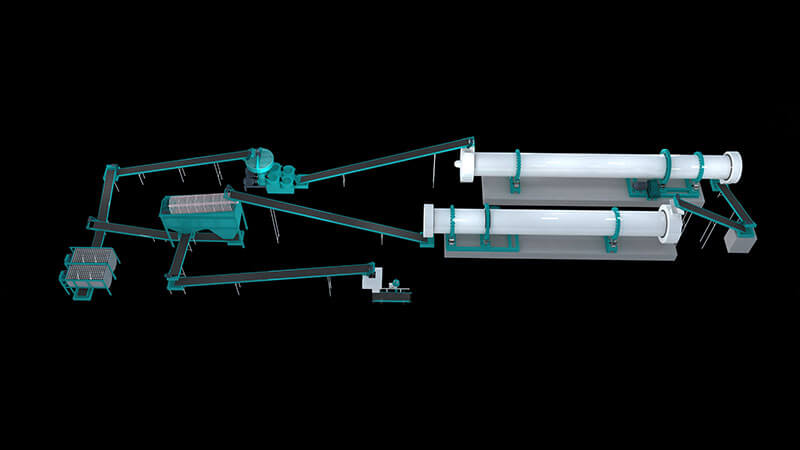

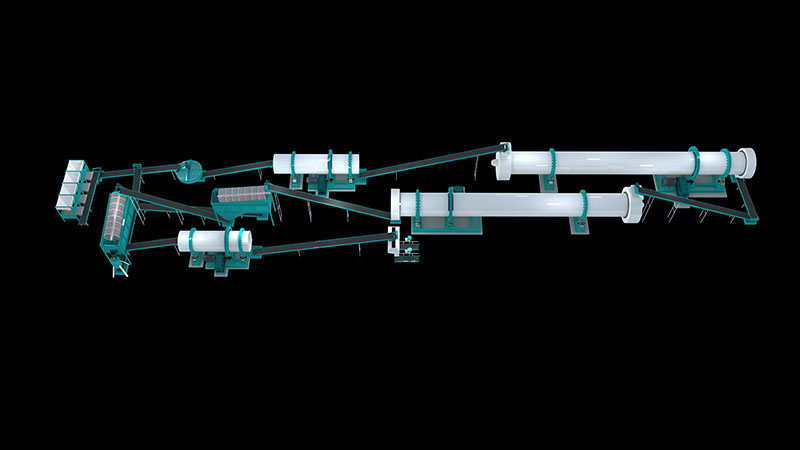

Main Parts of 20,000 Tons/year Bio Organic Fertilizer Production Line

Double Helix Compost Turner (raw materials fermentation) → Pan Feeder (smooth feeding) → High Moisture Fertilizer Crusher (fermented materials crushing) → Disc Granulator (materials granulating) → Rotary Drum Dryer (fertilizer drying) → Rotary Drum Cooler (fertilizer cooling) → Drum Sifting Machine (fertilizer screening) → Organic Fertilizer Coating Machine (finished products coating) → Automatic Packing Machine (fertilizer packaging) → Vertical Crusher (substandard products crushing for re-granulating) → Belt Conveyor (raw materials and finished products transporting)

Granulation Process of 20,000 Tons/year Organic Fertilizer Plant

1) Organic Materials Fermentation Process

This process plays the preliminary but indispensable role in the whole production line. There are 4 kinds of compost turns choosable for customers-double helix compost turner, self-propelled fertilizer turner, hydraulic compost mixer turner, and groove type fertilizer fermentation machine. They are widely used to turn and mix the compost and accelerate the fermentation speed.

2) Crushing Process

The compost lump materials should be ground before the granulation process. It is widely used in bio-fermentation of organic compost, MSW compost, carbon mud, rural straw waste, industrial organic waste, chicken manure, cow dung, sheep, pig, duck manure and other biological materials. The semi-wet material grinder is more suitable to crush lump compost fertilizer raw materials with moisture content between 25-55%.

3) Granulation Process

It is the core part in organic fertilizer production. Pan granulator is used in fertilizer plant with low output requirement. Fermented raw materials are uniformly bonded together due to the continuous rotation of the disc. Automatic cleaning equipment is installed in the upper part of the disc to prevent materials sticking to the wall, which greatly improves lifespan of the machine.

4) Drying Process

Rotary drum drying machine is mainly used for drying the fertilizer with a certain degree of humidity and particle size. Materials are transported to the drum by belt conveyor. Rotary dryer is suitable for large, medium, and small farms. Different sources of heat are applied, such as coal gas producer, directly/indirectly heated stove, etc., according to different drying requirements of products.

5) Cooling Process

Rotary drum cooler is used for cooling fertilizers to make fertilizer particles stronger.

6) Screening Process

Our rotary drum sifting machine is used to separate the granules from the large particles which need to be returned for the second crushing and granulating. Rotary drum coating machine is used to coat the fertilizer and prevent the fertilizer from sticking together.

Technical Data of Pan Granulator Organic Fertilizer Production Line

|

Item

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Quantity (set)

|

|

Pan Feeder

|

FY-YPWL-2000

|

2100x2100x1300

|

2.5-5

|

5.5

|

2

|

|

Pan Granulator

|

FY-YPZL-3000

|

3420x2480x2870

|

1.5-3

|

11

|

2

|

|

Rotary Drum Dryer

|

FY-HGJ-1.5

|

16300x2800x2260

|

3-5

|

11

|

1

|

|

Rotary Drum Cooler

|

FY-LQJ-1.2

|

16300x2800x2260

|

3-5

|

7.5

|

1

|

|

Rotary Drum Screening Machine

|

FY-GTSF-1.5×5

|

6300x1880x3450

|

3-7

|

7.5

|

2

|

|

Rotary Drum Coating Machine

|

FY-HBM-1.2×4

|

2-4

|

7.5

|

1

|

|

|

Vertical Crusher

|

FY-LSFS-60

|

1000x730x1700

|

1-5

|

15

|

1

|

|

Finished Products Warehouse

|

FY-CPC-2.0

|

2150x2150x4100

|

8-15

|

2

|

|

|

Automatic Packager

|

FY-DGS-50F

|

3-8bag(s)/minute

|

1.5

|

2

|

|

|

Belt Conveyor

|

8

|

||||

|

Dust Settling Chamber

|

Drawing is provided

|

1

|

|||

|

Hot Blast Stove

|

Drawing is provided

|

1

|