Raw Materials of Organic Fertilizer can be methane residue, agricultural waste, animal manure, and MSW. While all those organic waste need to be further processed before being turned into products with sales value. The large investment in Turning Trash into Treasure is absolutely well worth the money.

This organic fertilizer production line is equipped with groove type compost turner, rotary drum granulator, chain crusher, rotary drum dryer & cooler, rotary drum screening machine and other auxiliary fertilizer equipment. The annul output can be 30,000 tons. As a professional fertilizer production line manufacturer, we also supply the customers with other granulation lines with different production capacity, such as 20,000 T/Y, 50,000T/Y, and 100,000T/Y, etc.

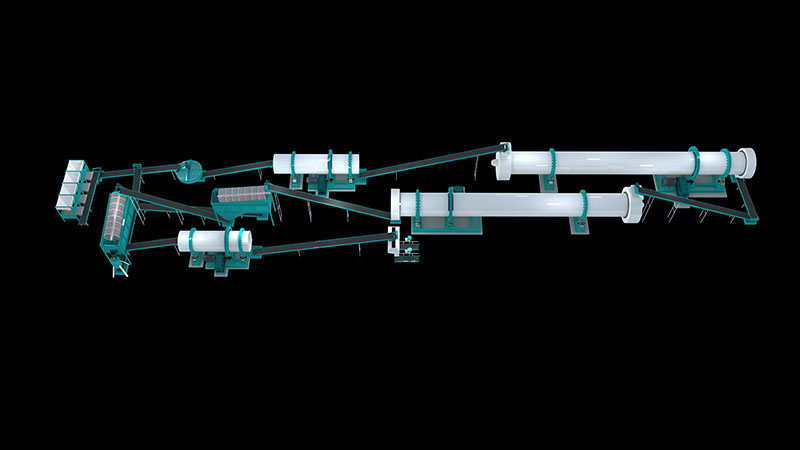

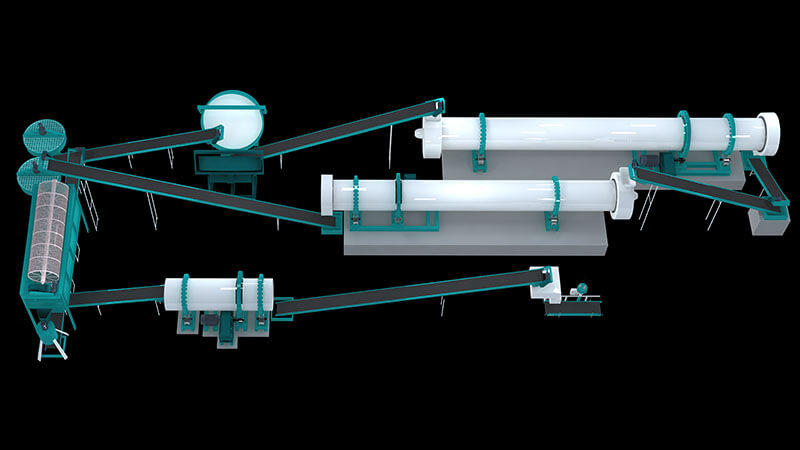

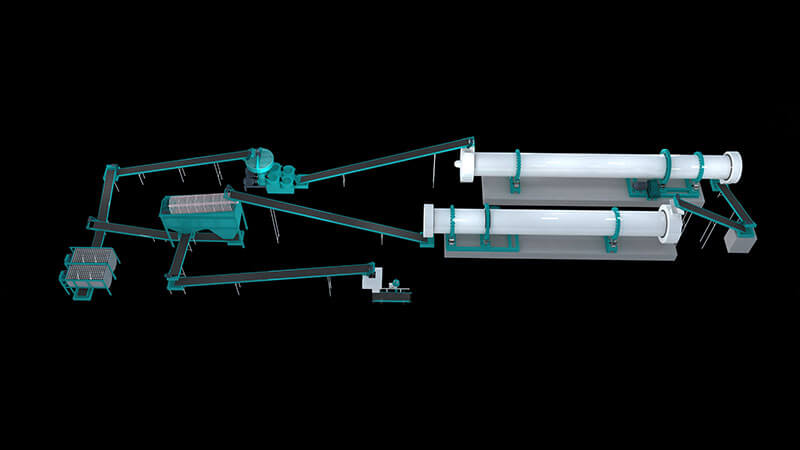

Flow Chart of 30,000 Tons Organic Fertilizer Manufacturing Plant

Raw materials pre-crushing (high moisture fertilizer crusher) → Organic materials fermentation (groove type compost turner) → Fermented materials crushing (high moisture fertilizer crusher)→ Granulating (rotary drum granulator) → Drying (rotary drum dryer) → Cooling (rotary drum cooler) → Finished products screening (rotary drum sifting machine) → Sub-standard granules crushing (vertical fertilizer chain crusher) → Coating (rotary drum coating machine) → Finished products packing (automatic quantitative packager) → Storage (storing in a cool dry place, tightly closed)

30,000 Tons Rotary Drum Granulator Production Process

1. Aerobic Fermentation

Gathering biodegradable raw materials in the working area. Lane turner (groove type fertilizer turner) is used for the fermentation and turning of livestock manure, sludge garbage, straw, sawdust and other organic wastes. Under the operation of vertically and horizontally walking gear, the high-speed disc harrows throw the fermentative materials up, then fall to the ground and the material shift. The fermented material is carried away and the space is cleared for the material requiring fermentation. Thus a complete fermentation process is formed.

2. Materials Crushing

Semi-wet fertilizer crusher, also called high moisture crushing machine, has two smashing systems, which helps to thin material particles below 3mm. It has a low moisture requirement on raw materials, as the allowable water content could be 35%, especially suitable for fermented organic material. High moisture fertilizer crusher is widely used in organic & bio-organic fertilizer production.

3.Materials Granulating

After crushing, materials are transported into rotary drum granulator by belt conveyor. With the constant rotating of drum, the materials form a rolling bed, and moves along a certain path. Under the extrusion force produced, the materials agglomerate into small particles, which become the core, attaching the powder around to form the qualified spherical granules.

| 4.Fertilizer Drying Material shall be dried to enter the dryer. When the dryer is rotating, a series of internal fins will lift the material by lining the inner wall of the dryer. When the material reaches certain height to roll the fins back, it will be fell back to the bottom of the dryer, then passing through the hot gas stream as it falls. Independent air hating system, centralize waste discharge result in energy and cost saving. |

|

5.Fertilizer Cooling Rotary drum cooler removes fertilizer water and lowers temperature, used with rotary dryer in organic fertilizer and in-organic fertilizer production, which greatly increases cooling speed, and relieves work intensification. The rotary cooler also can be used to cool other powdered & granular materials. |

6.Fertilizer sifting

Fertilizers are conveyed into the cylinder through the feed end. With the rotating of the cylinder, organic fertilizers are sifted. Larger granules flowing along the slope of the cylinder to move forward, and the materials are screened through different screens for different purposes. The sub-standard

Features of Organic Fertilizer Production Line

☞ High organic matter content, effectively improving soil fertility, suppressing soil-borne diseases;

☞ Improving Soil, neutralizing toxic substances, such as heavy metals, pesticides etc., and conditioning soil pH;

☞ Increasing utilization rate of fertilizers, improving the anti-adversity ability of crops;

☞ Improving crop resistance to pests and diseases, protecting flowers and fruits, and preventing physiological flowers & fruits drop;

☞ Increasing both production and revenue, being the preferred fertilizer choice in pollution-free, green, and organic production.

Organic Fertilizer Manufacturing Plant Technical Data

|

Item

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Quantity (set)

|

|

Pan Feeder

|

FY-YPWL-2000

|

2100x2100x1300

|

2.5-5

|

5.5

|

1

|

|

Rotary Drum Granulator

|

FY-ZGZL-15×60

|

6000x2600x2000

|

3-5

|

11

|

1

|

|

Rotary Drum Dryer

|

FY-HGJ-1.8

|

19500x3300x2450

|

6-10

|

22

|

1

|

|

Rotary Drum Cooler

|

FY-LQJ-1.5

|

19500x3300x2450

|

6-10

|

11

|

1

|

|

Rotary Drum Screening Machine

|

FY-GTSF-1.5×5

|

6300x1880x3450

|

3-7

|

7.5

|

2

|

|

Rotary Drum Coating Machine

|

FY-HBM-1.2×4

|

2-4

|

7.5

|

1

|

|

|

Vertical Crusher

|

FY-LSFS-80

|

1250x1000x2100

|

2-8

|

22

|

1

|

|

Finished Products Warehouse

|

FY-CPC-2.0

|

2150x2150x4100

|

8-15

|

2

|

|

|

Automatic Packager

|

FY-DGS-50F

|

3-8bag(s)/minute

|

1.5

|

2

|

|

|

Belt Conveyor

|

12

|

||||

|

Dust Settling Chamber

|

Drawing is provided

|

1

|

|||

|

Hot Blast Stove

|

Drawing is provided

|

1

|

NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.