Introduction of Double Roller Press Machine

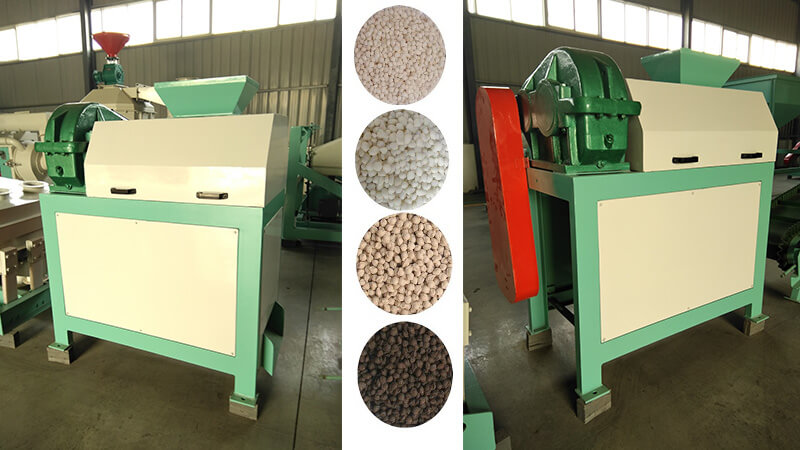

Our roller fertilizer making machine is a key fertilizer equipment in compound fertilizer granulation. Roller-type granulator is a new-designed fertilizer roller compaction granulation device developed & researched by ourselves. Materials are granulated at room temperature, and there is no drying process, more energy-saving and cost-reducing. With the characteristics of small investment, large profits, and quick results, the double roller compactor granulator will bring investors bigger economic returns. It can be used in compound fertilizer production with high, medium and low concentration.

Our roller fertilizer making machine is a key fertilizer equipment in compound fertilizer granulation. Roller-type granulator is a new-designed fertilizer roller compaction granulation device developed & researched by ourselves. Materials are granulated at room temperature, and there is no drying process, more energy-saving and cost-reducing. With the characteristics of small investment, large profits, and quick results, the double roller compactor granulator will bring investors bigger economic returns. It can be used in compound fertilizer production with high, medium and low concentration.

Advantages of Double Roller Fertilizer Granulation Machine

1.Reasonable structure. This roller fertilizer granulator machine is compact in design, light in  weight, steady in rotation, with higher precision and stiffness. The press rollers, which are accommodated to press different shapes/sizes materials, adopt new metal which is resistant to corrosion, oxidation, and abrasion. The double roller press machine is also with perfect performance, reliable operation, easy in maintenance and long service life.

weight, steady in rotation, with higher precision and stiffness. The press rollers, which are accommodated to press different shapes/sizes materials, adopt new metal which is resistant to corrosion, oxidation, and abrasion. The double roller press machine is also with perfect performance, reliable operation, easy in maintenance and long service life.

2.Wide application scope. At present, there are 20 kinds of raw materials being applied in this extrusion granulation, such as urea, ammonium nitrate, potassium chloride, bentonite, chicken  manure, pig manure, and other animal poultry manure waste etc. In addition, it can replace the product formula flexibly in a short time by adopting extrusion granulation technology . A set of device can produce over 30 product formulas.

manure, pig manure, and other animal poultry manure waste etc. In addition, it can replace the product formula flexibly in a short time by adopting extrusion granulation technology . A set of device can produce over 30 product formulas.

3. Making raw materials to fertilizer granules at once time. The roller compactor granulator has higher granulating ratio of over 85%. The granular shape of finished products pressed by double roller granulator is elliptical.

4. Environmental friendly. Reliable motor is used, no three wastes releasing which is environmental protection.

5. Lower energy consumption. There is no drying process. It doesn’t need oil or gas fired, bringing fertilizer investors good economic returns with low investment.

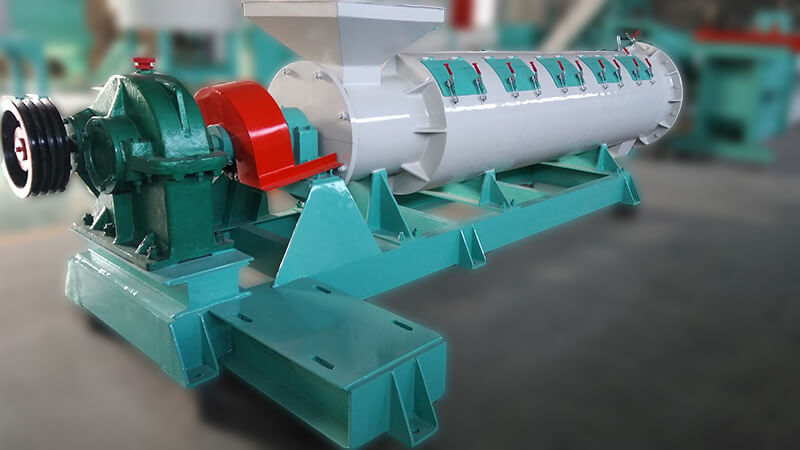

Working Process of Roller Fertilizer Making Machine

The double roller fertilizer granulator machine is the representative of extrusion granulator. Dry materials are compressed into hard & dense blocks at a  pressure, which is the Extruding Process. Block materials are crushed, screened and granulated later, which is the Granulating Process. The functions of extrusion are to squeeze the air between particles out, and to make the distance between particles near enough to give rise to interaction forces. The particle hardness of roller compaction granulation granules is formed mainly due to attraction between the molecules. Our double roller press machine is continuous extruding granulation of positive-displacement.

pressure, which is the Extruding Process. Block materials are crushed, screened and granulated later, which is the Granulating Process. The functions of extrusion are to squeeze the air between particles out, and to make the distance between particles near enough to give rise to interaction forces. The particle hardness of roller compaction granulation granules is formed mainly due to attraction between the molecules. Our double roller press machine is continuous extruding granulation of positive-displacement.

Application of Roller Press Machine

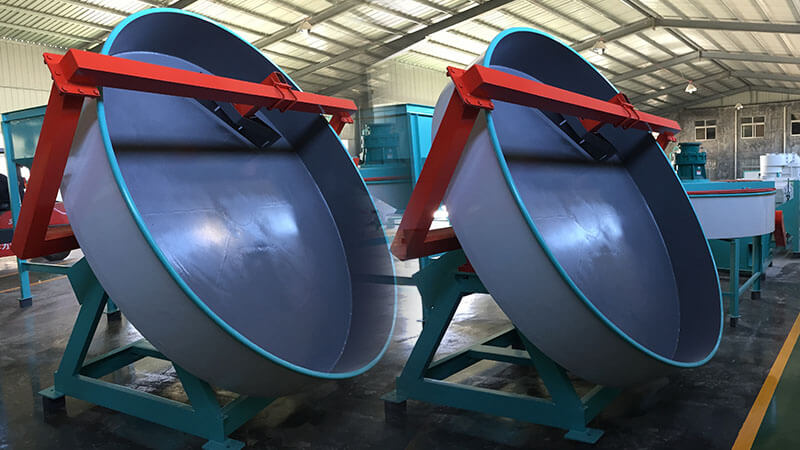

The double roller fertilizer making machine is used in 30,000 t/y compound fertilizer production line & other products manufacturing, such as capsule filling particles, pigments, detergents, catalysts, fertilizer, inorganic salts, calcium hypochlorite, pesticides, oxides, etc., industrial dust recovery materials: such as foundry dust, lead, zinc, aluminum dust, converter dust, grinding dust, etc.

The double roller fertilizer making machine is used in 30,000 t/y compound fertilizer production line & other products manufacturing, such as capsule filling particles, pigments, detergents, catalysts, fertilizer, inorganic salts, calcium hypochlorite, pesticides, oxides, etc., industrial dust recovery materials: such as foundry dust, lead, zinc, aluminum dust, converter dust, grinding dust, etc.

Remark:finished granules by this roller press machine is oval shape, if you want round ball shape granules,a ball shaping machine can help, ball shaping machine is used to make cylindrical and oval shape granules (pellets) into round ball shape granules. It adopts high speed rotation working principle to make round ball pellets.

Technical Data of Compound Fertilizer Granulator Machine

|

Model

|

Dimension L x W x H(mm)

|

Output (t/h)

|

Power (kw)

|

Material Moisture Content

|

Feed Size (mm)

|

|

FY-JYZL-1.0

|

1300x750x1300

|

0.75-1

|

15

|

2%-5%

|

≤0.5

|

|

FY-JYZL-1.5

|

1450x840x1500

|

1-1.5

|

22

|

2%-5%

|

≤0.5

|

|

FY-JYZL-2.0

|

1530x950x1650

|

1.5-2

|

37

|

2%-5%

|

≤0.5

|