Popularization of Vegetable Waste Organic Fertilizer

With the development of organic agriculture, the application of organic fertilizer is becoming more widespread around the world. In the meantime, the production technology of organic fertilizer is always developing, and vegetable waste organic fertilizer is more popular in various countries. The study shows that vegetable root, stem, and leaves contain a large amount of organic matter, which are good organic fertilizer resources. With the help of an organic fertilizer production line, composting vegetable waste and animal manure to produce fertilizer fully achieves the recycling of vegetable waste, reusing it in agricultural production, and enhancing its use value.

Vegetable waste is mainly produced by the vegetable market, then the farm and family. According to statistics, a city in India generates 500 tonnes of garbage every day, of which 50 tonnes are vegetable waste generated from vegetable markets and families. With the popularity of vegetable waste organic fertilizer, the heap of vegetables dumped at wholesale markets will no longer be the food for stray animals in the city. Now, the vegetable waste will be processed and converted into organic fertilizer for farmers with the development of organic farming. Around 200 tonnes of vegetable waste mixed with cow manure and straw can produce 60 tonnes of organic fertilizer.

We will use vegetable waste organic fertilizer for gardens and parks. When it will be carried on a large scale, the organic fertilizer, which contains nutrients like nitrogen, phosphorus, and carbon, will be sold to farmers. How to Produce Organic Fertilizer from Vegetable Waste?

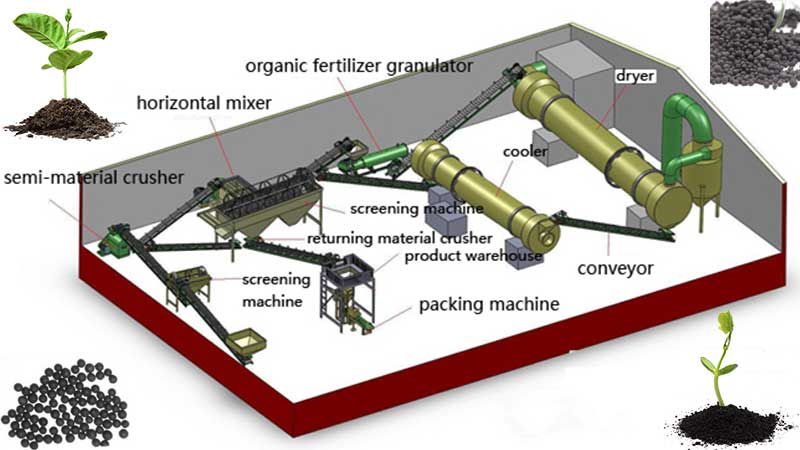

Large-scale vegetable waste fertilizer production often requires the aid of professional plant design, we can offer 20,000, 30,0000, and 50,000 three types of organic fertilizer production lines for customers.

Here are the basic steps of producing organic fertilizer from vegetable waste:

● Collection of vegetable waste for composting

Vegetable waste mainly includes onion, cauliflower, carrots, cauliflower, sweet corn, cabbage, lettuce, broccoli, beetroot, etc. For each of the vegetable crops, percentages of waste were estimated. In the case of cauliflower, approximately 70% of the crop may be marketed as premium, the 30% being wasted. Overall, 25% of vegetable production was estimated to go to waste.

Experiments were carried out to evaluate the possibility of recovering and recycling vegetable waste originally collected from vegetable markets. These vegetable wastes were biologically stabilized through composting in a pile in order to obtain humified organic matter (green compost) to be used as an agricultural soil conditioner. Vegetable waste provides a good amount of nutrients for microorganisms during composting. The vegetable waste containing lettuce and onion waste has high amounts of sulfur 0.2% and 0.7% respectively; their moisture content is of 96.2% and 91.1% respectively. High C:N

The suitable temperature for fermentation is 25°C to 37°C and the optimum pH is around 4.0 to 5.5. Self-propelled compost turner always plays an important role in the fermentation process. With the help of a compost turner machine, the whole vegetable waste fermentation period is about 15-20 days. Compost is a partially stabilized product of microbial decomposition of organic materials. The microorganisms and the nutrients present in the raw materials are very helpful in improving soil health. Vegetable waste compost can increase the water and nutrient holding capacity of sandy soils; increase the aeration and internal drainage of clay soils; add nutrients; increase soil microorganisms; and suppress some plant diseases.

● Crushing & Mixing Vegetable Waste

After a period of composting, vegetable waste also has high moisture and needs to be crushed by fertilizer crushing machine. Our fertilizer chain crusher is suitable for high-moisture raw materials, of which the moisture content can reach 20%-55%. The moisture of vegetable waste compost is greatly reduced while crushing, and the crushing degree can meet the requirement of granulation.

After crushing, the crushed vegetable waste is sent to the horizontal fertilizer mixer. With the fertilizer mixer’s help, the vegetable waste can be mixed evenly, and high mixing homogeneity is greatly improved, convenient for granulation.

● Granulating

Granular organic fertilizer is the most frequently used around the world. It is more convenient than powdery organic fertilizer, and easily absorbed by the soil. Put the crushed vegetable waste compost into our new type organic fertilizer granulator, then the raw material is processed into uniform particles with a high-speed rotating force. Our new type of granulation machine breaks the conventional organic granulation technology that can process raw materials into uniform spheroidal particles without a drying process. The qualified rate of particles is up to 95%, and granular organic fertilizer can be screened directly.

● Screening& Packing

After granulation, the production of vegetable waste organic fertilizer is mainly completed. However, some particles are large can’t meet the quality requirements, and have to be separated by a rotary drum screening machine. The screening process is mainly to separate the qualified and unqualified organic fertilizers. Large particles will be selected for the next round of granulation. The qualified organic fertilizer is sent to be packed by an automatic packing machine.

What are the Benefits of Producing Organic Fertilizer from Vegetable Waste?

◆ The application of vegetable waste organic fertilizer effectively solves the handling problem of vegetable waste, achieving sustainable use of resources and reducing environmental pollution.

◆ It is a very low-cost process to convert vegetable wastes into organic fertilizer. The production completed by the organic fertilizer production line is high efficiency, energy-saving, and environmentally friendly.

◆ Turning trash into treasure, enhancing the use value of vegetable waste. A ton of vegetable waste is processed into organic manure that can add the value of one hundred dollars.

◆ Effective decrease of the usage of chemical fertilizers and pesticides. Organic fertilizer produced from vegetable waste contains a large amount of organic matter, beneficial microorganism, and trace elements and greatly improve the soil structure.

◆ The vegetable waste organic fertilizer doesn’t pollute the environment, reaching the ecological concept of environmental protection and bringing new vitality to the vast variety of vegetable plants.

Related Posts:

Sheep Manure Commercial Organic Fertilizer Making Technology

Filter Press Mud& Molasses Compost Fertilizer Making Process

Horse Manure Organic Fertilizer Compost and Production

Biogas Waste to Energy-Biogas Fertilizer Production Solution